Water heater electrostatic enamel powder

GET FREE SAMPLES!General Usage:

It is a high quality water heater electrostatic enamel powder, especially for electric/solar/air energy water heaters, and water storage boilers.

Product Description:

| Property | Details | |

|---|---|---|

| Product trade name | Water heater electrostatic enamel powder | |

| Product code | E-1991 | |

| Main application scope | Water heater/Heater exchange etc. Used as a surface coating material | |

| Limitations | None | |

| Adherence | Grade1-2 | |

| Dry powder adhesion | >70% | |

| Flowability | 140±10g/30sec | |

| Acid resistance test | A+—AA | |

| Optimal application thickness | 100-150μm | |

| Typical Physical Properties: | Odor | Odorless |

| Vapour pressure | None | |

| Flash point | None | |

| Ignition point | None | |

| Explosion limit | None | |

| Fineness | 100g200mesh sieving Sieve residue1.5-3g | |

| Enamel product surface | No surface defects. | |

| Optimal firing temperature | 850℃ | |

Noli Frit Enamel Powder Quality Test Report

| Test Item | Test Protocol | Status | Compliance Standard |

|---|---|---|---|

| FLUIDITY TEST | Granular flow characteristics analysis | Pass | ISO/DIS 8130-5 |

| Adhesion Test | Substrate bonding performance | Pass | European Enamel Association Sec.8.4.3 |

| Resistivity Test | Electrical resistance measurement | Pass | European Enamel Association Sec.8.4.4 |

| Coating Thickness | Layer depth verification | Pass | IS 13273:1991 (5.3.3) |

| Impact Resistance | Mechanical stress simulation | Pass | IS 13273:1991 (5.3.2.5) |

| Citric Acid Test | Chemical corrosion resistance | Pass | IS 13273:1991 (5.3.2.2) |

| Thermal Shock | Rapid temperature cycling | Pass | IS 13273:1991 (5.3.2.4) |

| Visual Inspection | Surface defect identification | Pass | Internal QS-045 |

| Conclusion : Through rigorous IQC (Incoming Quality Control) and IPQC (In-Process Quality Control) procedures, Noli frit enamel powder has demonstrated exceptional performance characteristics across all test parameters when applied to flat surfaces, door components, and tank assemblies. | |||

1. FLUIDITY TEST

Pass

· Checking the Adhesion quality of Vitreous Enamel Powder on sheet metal.

· This device is designed to measure the adhesion force of electrostatic applied powder enamel, in accordance with section 8.4.3 of the Quality Requirements as published by the European Enamel Authorities.

| S.No | Product code | Maximum height H1 (mm) | Minimum height H0 (mm) | Mass of the powder Collected (g) | Suitability factor (R) | Remarks |

|---|---|---|---|---|---|---|

| 1 | E-1991 | 45 | 30 | 100 | 150.00 | Very good |

| 2 | E-1991 | 47 | 31 | 110 | 166.77 | Very good |

The quality suitability factor (R) is rated as Bad (<80), Poor (80-120), Good (120-140), and Very Good (>140).

2. ADHENSION TEST

Pass

· Checking the Adhesion quality of Vitreous Enamel Powder on sheet metal.

· This device is designed to measure the adhesion force of electrostatic applied powder enamel, in accordance with section 8.4.3 of the Quality Requirements as published by the European Enamel Authorities.

| RESULT = | Weight of the sprayed plate ( g ) - Weight of the hammered Plate ( g ) | ×100 | |

|---|---|---|---|

| Weight of the sprayed plate ( g ) - Weight of the plate ( g ) | |||

| S.No | Product code | Weight of the plate (g) | Weight of the sprayed plate (g) | Weight of hammered plate (g) | Adhesion Strength Percentage (R) | Remarks |

|---|---|---|---|---|---|---|

| 1 | E-1991 | 630 | 670 | 662 | 80 | Good |

The quality suitability factor (R) is rated as Very Poor (<40), Poor (40-60), Good (60-80), and Very Good (>80).

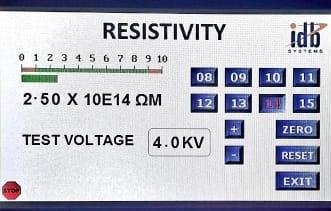

3. RESISTIVITY TEST

Pass

Resistivity : 2.50 X 10E14 ΩM

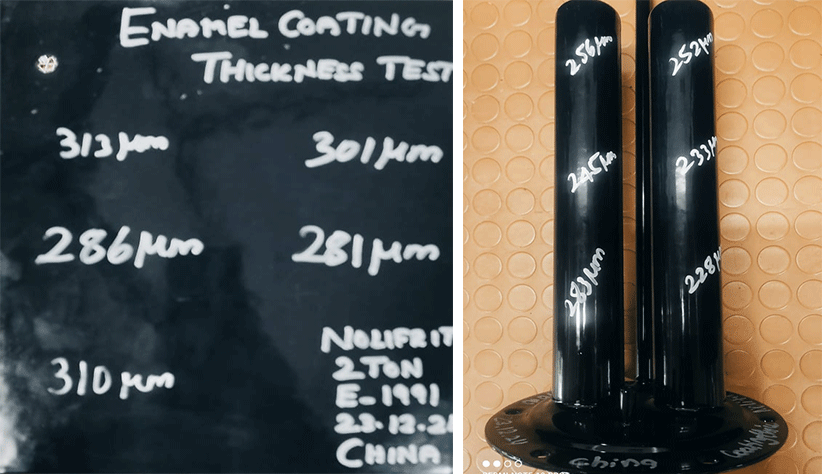

4. ENAMEL THICKNESS

Pass

· The thickness of the enamel coating shall be between 200µm to 400µm.

· The below test conducted on Sample Flat plate & Enamel Element Assembly(EEA):

| Sl.no | Top (µm) | Middle (µm) | Bottom (µm) | Results |

|---|---|---|---|---|

| 1 | 298 | 286 | 265 | OK |

| 2 | 321 | 281 | 256 | OK |

| 3 | 284 | 275 | 275 | OK |

| 4 | 276 | 295 | 285 | OK |

| 5 | 264 | 269 | 265 | OK |

| 6 | 285 | 274 | 279 | OK |

| 7 | 295 | 291 | 284 | OK |

| 8 | 264 | 304 | 295 | OK |

| 9 | 284 | 315 | 306 | OK |

| 10 | 298 | 295 | 315 | OK |

| Average | 287 | 289 | 283 | PASS |

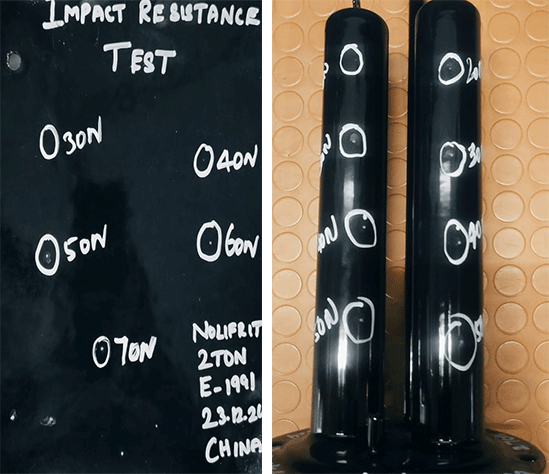

5. IMPACT RESISTANCE TEST

Pass

· Impact Testing is carried out by varying the limits in the impact ranger and the test is been carried out at 20N - 50N force range.

· The below test conducted on Sample Flat plate & Enamel element assembly(EEA) :

| Flat plate | Enamel element assembly | ||||||

| Sl.No | Tested ( N ) | Ok/Not Ok | Sl.No | Tested ( N ) | Ok/Not Ok | ||

| 1 | 20 | OK | 1 | 20 | OK | ||

| 2 | 30 | OK | 2 | 30 | OK | ||

| 3 | 40 | OK | 3 | 40 | OK | ||

| 4 | 50 | OK | 4 | 50 | OK | ||

Remarks : No Enamel chipping observed upto 50N and considered as PASS as per IS 13273 : 1991 (5.3.2.5)

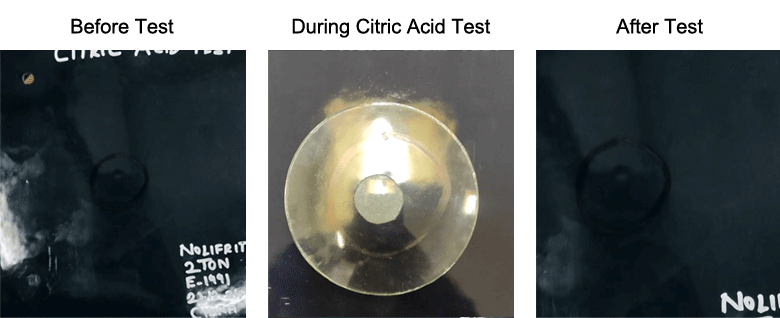

6. CITRIC ACID TEST

Pass

· The enamel shall pass the resistance to citric acid test at room temperature for 'AA' or 'A'class when tested by the method prescribed in 5 of IS 3972 ( Part 2/Sec 1 ) : 1985.

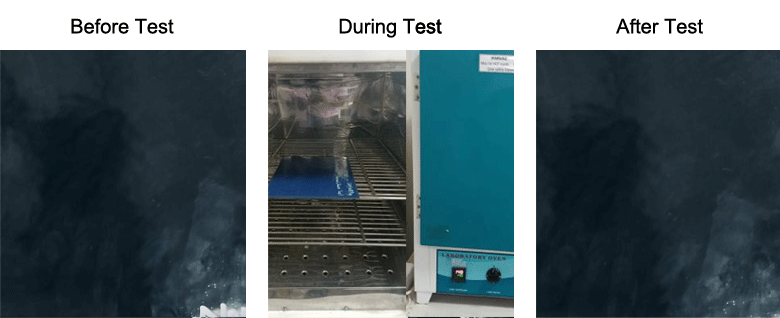

7. THERMAL SHOCK TEST

Pass

· The enamel shall pass the resistance to thermal shock test when tested by the procedure given below,

1. Test the samples with maintain the temperature at 140±3 deg celsius at laboratory oven.

2. After 30min completion inside oven, take the sample and drop into the water immediately.

3. After cooldown of the test samples, it shall not show any " Cracks or Flakes or Blisters ".

8.VISUAL INSPECTION

Pass

1.Flat Plate - No enamel defects were found.

2.Enamel Element Assembly - Trial conducted 10 No's, no enamel defects were found.

3.Tank(Boiler) - Trial conducted on tanks,All tanks passed without rework & rejection and also boilers were passed in coating thickness inspection,Impact resistance & Hammer test .

FREE SAMPLES, please add WhatsApp +86-13574208778 , Email: jack@nolifrit.com OR fill out the following form. We will respond to you as soon as possible.