Why Is Electrostatic Enamel Powder Widely Used?

The dry powder coating method is the earliest enamel coating method in historical records. In the 20th century, a new type of dry powder coating method appeared: electrostatic enamel powder coating, which is called "one of the greatest achievements of the coating process" , Its appearance has made the production of many enamel products easier, so it is widely used in countries all over the world. It is often used in household appliances such as microwave ovens, dishwashers, water heaters, washing machines, or kitchen appliances and buildings. In my country, electrostatic enamel powder technology is applied. The most common is the high-end oven industry, especially the built-in electric oven. The inner container and the main exterior parts are all coated with electrostatic powder.

The main advantages of electrostatic enamel powder:

1. The utilization rate of enamel can be as high as 97%~98%;

2. Improve the gloss of the porcelain surface and reduce the defects of the porcelain surface at the edge;

3. Two enamel and one firing process can be used, and no special decarburized steel plate is required;

4. The dry powder of enamel is used directly without grinding into enamel slurry, and the drying procedure after spraying is omitted.

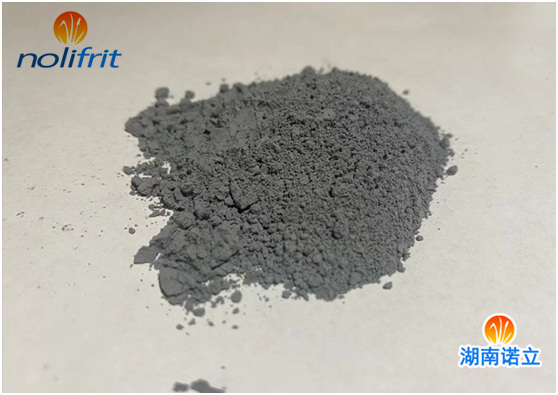

Compared with other organic coating powders, electrostatic enamel powder is unique in that it is very abrasive and denser, which is 2 to 3 times that of other organic powders. The electrostatic enamel powder is wrapped with organosilane to control the electrostatic characteristics. It is more sensitive to relative humidity, and a humid environment will cause the resistivity to drop by several orders of magnitude.

Although the electrostatic enamel powder has outstanding advantages, the spraying equipment it needs is bulky, not suitable for the production of small batch products, nor can it be used for products with overly complex shapes, and the electrostatic enamel powder cannot be added with pigments. Many friends can't distinguish the difference between enamel ready to use powder and electrostatic enamel powder. The enamel pre-grinding powder needs to be mixed with water for wet coating, while the electrostatic enamel powder is electrostatic enamel powder coating in the electrostatic enamel powder spraying room after adding the electrostatic coating agent.