Why Enamel Colors Must Be Formulated Through Professional Toning?

Enamel pigments are high-temperature resistant inorganic pigments, and compared to organic pigments, the variety of enamel pigments is relatively limited. Most enamel colors are formulated from two or more enamel pigments. Therefore, if enamel manufacturers require a specific enamel color, they need to achieve this through the milling and mixing of enamel pigments (i.e., toning color).

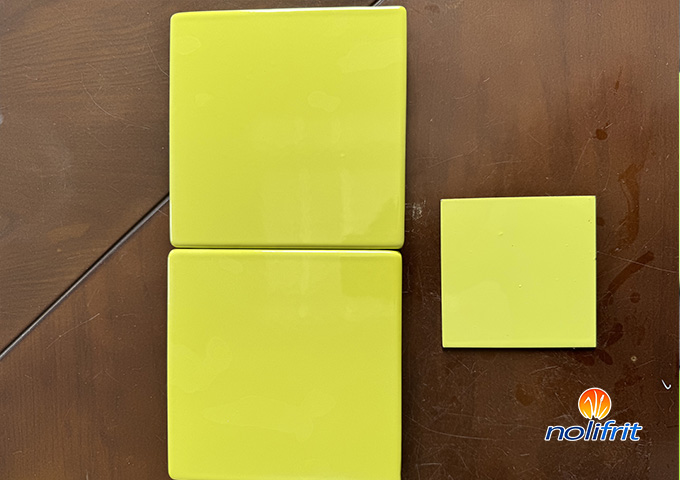

Toning color for enamel is a technical task that must be performed by professional technicians using colorimeters. It requires knowledge of pigments, enamel glazes, and firing processes, as well as the establishment of a database that records the colorimetric values of various pigments in the base enamel glaze.To formulate an enamel color, the first step is to determine the appropriate base enamel glaze based on the brightness value of the color sample. Then, the technician searches the established database for pigments with colorimetric values that closely match the color sample. After repeated mixing, sampling, comparison, and adjustments, the final glaze composition, coating, firing, and porcelain layer thickness, along with other relevant process parameters, are meticulously recorded as a guideline for production operations.

As a professional factory of enamel glaze materials, Nolifrit is dedicated not only to the research and production of high-quality enamel glazes but also to providing comprehensive technical services and customized professional solutions to customers. To date, we have successfully offered precise enamel toning color services to hundreds of customer’s enterprises, effectively solving many practical challenges faced by enameled products manufacturers. If you have related needs, feel free to contact us at any time!