What To Do If Enamel Corrugated Plate Explodes

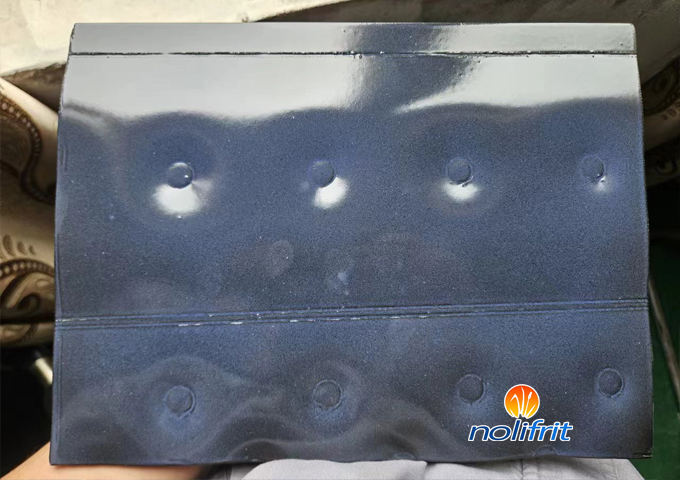

Recently, a manufacturer specializing in the production of enameled corrugated plates encountered a thorny problem: the newly produced double-layer enameled corrugated plates frequently exploded at the welding point. This not only affects the appearance quality of the product, but also poses a potential threat to the overall performance of the product.

In view of the severity of the problem, the enamel manufacturer, based on the long-term solid and trusting cooperation foundation with Nolifrit Company, and the deep trust in its professional ability and service quality, resolutely decided to entrust this challenging problem to Nolifrit for a solution.

After in-depth communication with the other party, the Noli technical team quickly launched a series of tests and studies. After many attempts, the technicians found that annealing the corrugated plate at 800℃ can effectively eliminate metal stress and thus avoid the occurrence of explosion problems. This discovery not only solves the urgent needs of enameled corrugated plate manufacturers, but also provides a new solution for the entire enamel industry.

As an enamel frit manufacturer, Nolifrit Company, with its professional technical team and one-stop service capabilities, has won the trust and praise of customers while helping customers solve problems. They not only provided effective solutions, but also actively communicated with manufacturers to ensure the effective implementation of the solutions and follow-up of the results.

For enamel manufacturers, this case is undoubtedly an important revelation. While pursuing product performance, we cannot ignore the details in the production process. A small improvement can often bring unexpected results. At the same time, maintaining close contact and communication with professional partners is also the key to ensuring product quality and technological innovation. If you have any related questions, please contact us!