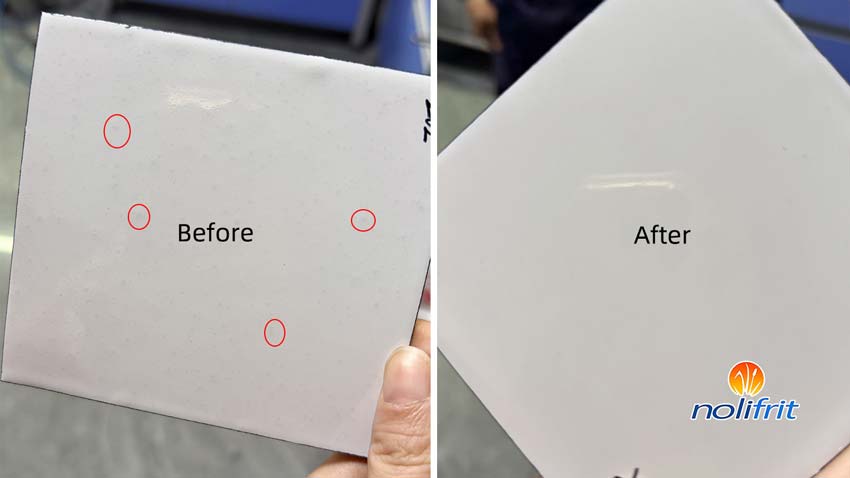

What should be done if black spots appear on enamelware made with white enamel frit?

Even though the enamel frit itself has no quality issues and the enamel process follows standard procedures, black spots still appear on products made with white enamel frit. Despite thorough investigations, the source remains elusive. Why is this happening?

After investigating the actual production conditions at the enamelware factory, Nolifrit's technical experts found that the core problem was concentrated on the discharge port cover of the large ball mill. If the cover is made of rubber or plastic, trace amounts of organic impurities are easily generated during ball milling. These impurities mix with the enamel and, after high-temperature sintering, form black spots. Therefore, it is recommended to replace these covers with ceramic or iron materials to reduce impurity generation at the source.

Furthermore, if the sealing ring on the cover is made of plastic or rubber, it can also cause contamination. Experienced factories will wrap the sealing ring with wet kaolin clay to prevent direct contact with the enamel, effectively avoiding the risk of black spots. An easily overlooked accessory and attention to detail often become the key to determining product quality.

This case profoundly illustrates the industry truth that “enamel details determine success or failure.” Enamel production is an interconnected system engineering process. From raw material storage and ball milling to glazing, sintering, and cooling, every step conceals detail factors that impact quality. Beyond easily overlooked components like ball mill lids, factors such as equipment cleanliness, operator hand hygiene, workshop dust control, and material compatibility of auxiliary supplies can all become sources of defects. These minor oversights act like hidden killers within the process, quietly triggering quality issues even when core steps appear flawless.

If you're grappling with enamel defects that persist despite thorough core process inspections, consult us. Leveraging extensive expertise, we deliver specialized solutions to help enamel manufacturers overcome bottlenecks. Details determine success, professionalism ensures quality—ensuring every enamel product emerges flawless.