Two Kinds of Determination Methods of

Acid Resistance Properties of Daily-use Enamelware

Daily-use enamelware is often in contact with food, soup, seasoning, etc., so acid resistance is also one of the important criteria. In addition to the citric acid test, the weight loss method and the trace method can also be used.

1. Weight loss method

Clean the sample, use a ratio of 1.5 milliliters of 4% acetic acid per square centimeter of immersion area, measure 4% (percentage by weight) of acetic acid solution with a graduated cylinder and inject it into the cup to be tested, record the liquid level, and place Heat on a 600W electric stove and boil slightly for one hour. During the boiling process, the evaporated acid liquid is replenished at any time to keep the liquid level at the same height. After cooling, adjust to the original liquid level with the original acid solution, stir evenly with a glass rod, draw 100 ml with a pipette and pour it into a beaker with constant weight. Evaporate to dryness on the heating electrode, then dry in an oven at 100~105°C, and weigh until constant weight.

Weight loss calculation method:

W=0015 (A2-A1 ) x1000

In the formula

W——weight of sediment per unit area, mg/cm²;

A2 - the weight of the container and the sediment, in grams;

A1——the weight of the container, in grams.

Calculation of the amount of acid used in the barrel-shaped sample:

V=πR²H

V=1.5F=1.5 (πR²+2πRH)

That is, 1.5 (πR²+2πRH) = πR²H

So H=1.5R/R-3

In the formula

V - the number of milliliters of acetic acid solution contained in the sample;

R - the radius of the cylindrical sample;

H - the height of the vinegar solution;

F - the area of the sample subjected to the action of the acid solution.

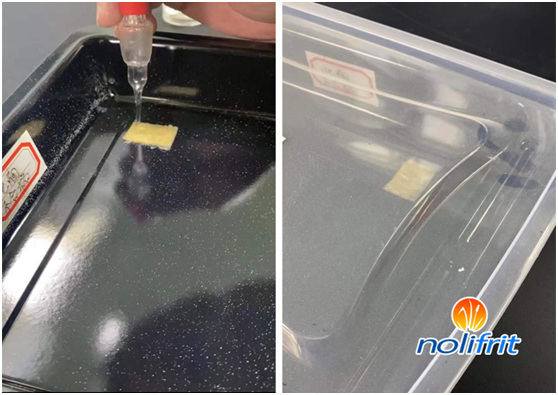

2. Trace method

Suitable for miscellaneous products.

Soak the filter paper strips in 0.2% (weight percent) acetic acid solution. Take out the filter paper strip and stick it to the inside of the sample to be tested, and let it stand at room temperature for 20 minutes. Remove the filter paper strip, wash and dry the sample with water, smear it with manganese dioxide above 200 mesh, and then wipe it with absorbent cotton. There must be no traces of pollution on the surface of the corroded area.

If you want to improve the acid resistance of enamel products, you can use acid-resistant glaze. Nolifrit is a supplier of enamel frits and enamel pigments. If you have any related needs, please contact us!