The Factors That Affect the Adhesion of Enamel

With the continuous improvement of people's living standards, the production process of enamel products has gradually changed. On the one hand, the improvement of technology has gradually improved the production process of enamel products. On the other hand, consumers' aesthetic concept has been continuously improved, and they are increasingly inclined to fashion and personality. Therefore, in the production process of enamel products, we must also comprehensively consider how to choose enamel raw materials. In this arcticle, Nolifrit will tell you what factors affect the adhesion strength of enamel products.

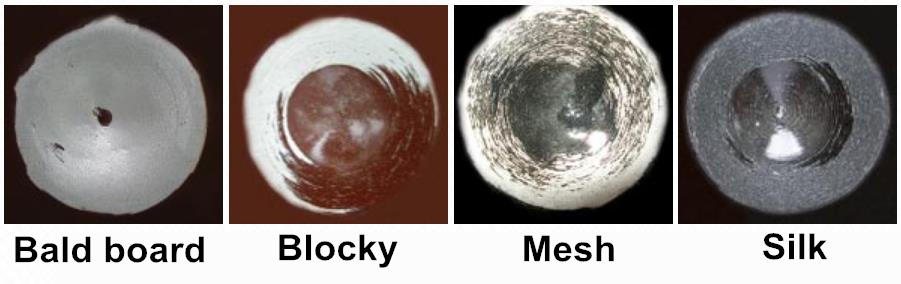

The adhesion of enamel reflects the pros and cons of the combination of the enamel ground coat layer and the metal body. It is judged by the degree to which the ground coat layer exposes the metal after the enamel surface is impacted. It is generally divided into silk, mesh, block and bald, of which the silk shape is the best, the net shape is the second best, the block shape is so so, and the bald board is the worst.

Silk: After the enamel layer is tested, there are a few dots and linear metal exposed after the enamel layer is peeled off.

Mesh: The enamel layer is exposed to metal like a mesh after peeling off.

Blocky: A large area of exposed metal appears after the enamel layer is peeled off, and there is only a little groundcoat at the test point.

Bald board: The metal is fully exposed after the enamel layer is peeled off.

The adhesion performance of enamel has a great relationship with the surface tension of the enamel melt. The enamel with high surface tension and poor wettability cannot produce good adhesion with metal. The melting degree of the ground coat also has a great relationship with the adhesion strength. Excessive melting or incomplete melting are both not good to the adhesion of the enamel, and other defects will also occur. The firing process is also very important to the adhesion strength of enamel products. The adhesion of enamel products will be poor with both excessive firing or insufficient firing.

In addition to the above factors that can affect the adhesion strength of enamel products, some enamel material factories will introduce adhesion agents in the enamel, which can promote the erosion of the enamel melt on the metal surface. The greater the erosion, the more conducive to adhesion. The adhesion strength is not only related to the type and quantity of the introduced adhesive, but also closely related to the surface condition and cleanliness of the metal. A substrate with rough surface has a much better adhesion strength than that with smooth surface.