The Causes of Enamel Chipping-off and Solutions

The defects of the enamel products mainly refer to the damage of the continuous structure of the enamel layer, such as pinholes, bubbles, cracking, chip and color difference and reduction of gloss. The defects mainly caused by the water vapor, hydrogen, carbon dioxide, carbon monoxide and other gases generated in high temperature fusion of metal body and enamel layer, as well as the stress between metal body and enamel layer. Nolifrit experts will show the analysis of the causes of chipping-off of enamel products and how to deal with them.

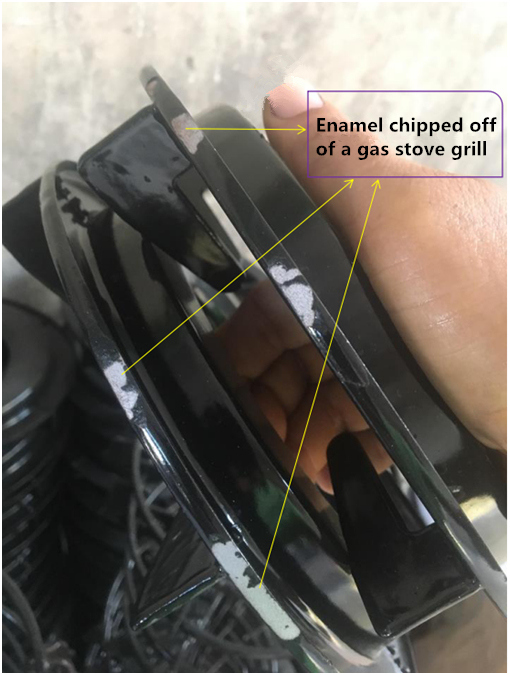

Chipping-off means that the enamel layer is detached from the product in pieces, and some of the ground coat is exposed or even some the metal surface exposed.

The reasons for enamel chipping-off are as follows:

1, The stress is too large:

For example, if the selected enamel frit has a relatively hard texture and small expansion coefficient, the elasticity is insufficient, this will make the internal stress is too large. For this, enamel frit with better elasticity can effectively improve this situation. At the same time, if the radius of curvature of the metal body is too small, it will also cause excessive internal stress. Therefore, when designing the product, the requirements of the enamel process should be fully considered. Appropriate increase radius of curvature the edge, handle, foot, and bottom, makes the turning part more moderate. This is a more effective method.

2, Poor adhesion:

If the pretreatment of steel plate is not suitable, the ground coat will not completely infiltrate the steel substrate, resulting in poor adhesion; Poor quality or insufficient dosage of the adhesive, under sintering (low furnace temperature or short time) will result in insufficient adhesion formation. At this time, it is necessary to adjust the design of the pretreatment, the choice of enamel frit and adhesive, firing temperature and time. With better adhesion, the defect of chipping-off will naturally reduced.

3. Other causes:

The following factors, such as excessive iron pickling time, which produce a large amount of hydrogen; Too much soluble salt contained in enamel slip; The edge frit is ground too fine, excessive storage time of enamel slip. Excessive thickness of enamel layer which causes insufficient firing; Repeated firing; Acceleration of cooling. Ground coat surface contamination causes the poor bonding of ground coat with cover coat; Cracking of the enamel layer caused by impact of the semi-finished product.

All of the above-mentioned causes of defects are objective existed and inevitable. If the production is carefully and strictly organized in accordance with the mature production process, the defects of the product will be greatly reduced.