The Application & Features of Industrial Enamel

As we all know, industrial enamel should have high acid resistance, certain alkali resistance, heat resistance, impact resistance and excellent coating and firing performance. But for a long time, industrial enamel have weaknesses such as high firing temperature, poor rheological properties of enamel slurry, and short product life.

The physical and chemical properties of enamel are very stable, so it is used in many special industries. In order to meet these conditions, the enamel frit formula and composition will be different for these applications. Today, Nolifrit introduces industrial enamel to everyone about its application and features of industrial enamel frit.

Industrial enamel mainly refers to chemical equipments used in acid and alkali resistance, such as chemical reaction kettles (pots), stirring paddles, valves, chemical containers and other industrial enamel products.

Features of industrial enamel frit:

Most industrial enamel frits are used in chemical equipments. These equipments are chemically reacted under high temperature and high pressure. Most of the contact is with strong acid and alkali solutions. Nolifrit summarized that enamel frit needs to have the following features:

1. The adhesion is strong.

2. During firing, defects such as bubbles, pores, or focal points are not allowed.

3. Good acid resistance, alkali resistance and chemical stability.

4. Good thermal stability.

5. Good mechanical strength.

With the special chemical composition and product structure, the industrial enamel products required that the firing range of industrial enamel frit is relatively wide. Therefore, composite groundcoat is used, that is, there are two or more types of groundcoats in a certain proportion, and at the same time grinding and adding a large amount of quartz constitutes an industrial enamel composite groundcoat.

Hunan Noli Enamel Co., Ltd have developed industrial enamel frit for industrial enamels. Its features are as follows:

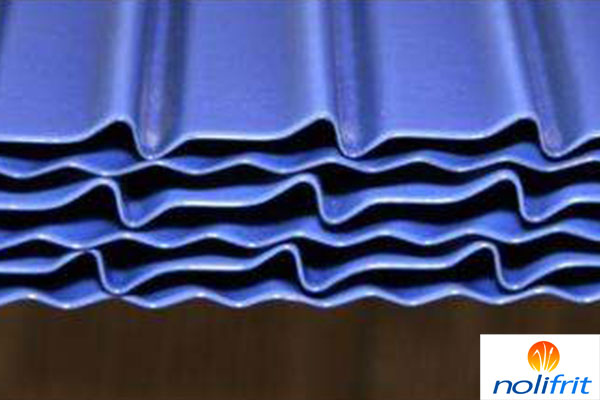

1. It is suitable for the enamel surface treatment of industrial equipment such as desulfurization and denitrification heat exchange elements, air preheater pipe fittings, chemical containers, reactors, stirring blades, etc. in thermal power plants;

2. It has the features of low firing temperature and strong resistance to re-firing;

3. Good operation performance, high strength of the enamel layer;

4. Resistant to strong chemical corrosion.