Specific Gravity of Enamel Slurry

Before applying enamel coating, it is necessary to grind the enamel frit, clay, water, electrolyte and other abrasives into a slurry. This is called the enamel slurry. The specific gravity (volume mass) of enamel slurry is one of the most important process performance indicators of enamel slurry.

First, the specific gravity of the enamel slurry affects the enameling operation. Too high specific gravity means that the enamel slurry is too thick and the fluidity is too small, and the specific gravity is too low to indicate that the enamel slurry is too thin and the fluidity is too large, which will make enamelling difficult;

Second, the specific gravity of the enamel slurry also affects the quality and appearance of enamel products. If the enamel slurry is too thin, the specific gravity will be small, which will result in a thin coating of the enamel slurry. The ground coat will burn easily and the adhesion strength will deteriorate, which may cause the porcelain to burst, and the cover coat will result in poor hiding power.

If the enamel slurry is too thick, the volume will be large, and the coating of the enamel slurry will be thick, which will cause insufficient firing of the enamel. The ground coat will boil and the adhesion strength will be poor. Poor gloss, rough porcelain surface, poor temperature resistance and other problems. Therefore, after the enamel manufacturer discovers the defect of the enamel product, if it is the specific gravity of the enamel slurry, it can be analyzed from the above reasons.

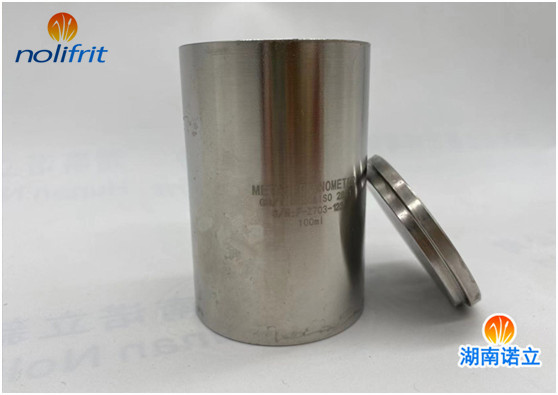

Measuring method of enamel slurry specific gravity:

First weigh the 100ml density cup with an electronic balance, and remove the tare weight of the density cup. Then pour the enamel slurry into the density cup, cover it tightly with a lid until the excess enamel slurry is completely overflowed, wipe the overflowing enamel slurry clean, and then weigh it on an electronic balance. The final mass is the specific gravity of the enamel slurry. Note that if the water content of the enamel slurry is larger, the specific gravity of the enamel slurry is smaller.

Commonly used enamel slurry specific gravity table (unit: g/100ml), for reference, it is recommended that enamel manufacturers and related practitioners keep it.

Ground coat: 160~165 g/ml

Titanium enamel: 165~170 g/ml

Edge enamel: 160~170 g/ml

Transparent enamel: 170~175 g/ml

Direct-on glossy enamel: 168~175 g/ml

Cast iron white ground coat (pots): 162~164 g/ml

Direct-on enamel for the inner tank of the water heater: 176~185 g/ml

If you have any other questions, please leave a message for consultation!