Properties of Desulfurization Board Enamel Frit

The desulfurization and denitrification board is a relatively mature application field of vitreous enamel, which is mainly used in boiler equipment in the industrial fields such as thermal power generation, petroleum and chemical industry. The desulfurization board is mainly used for air preheater and flue gas desulfurization and denitration. Due to the long-term exposure to strong corrosive environment, ordinary desulfurization board has a short service life and needs to be replaced frequently. The emergence of enamel desulfurization board solves this problem. Compared with ordinary enamel frit, what properties do desulfurization board enamel frit required?

1. Excellent corrosion resistance

Whether it is flue gas desulfurization or denitrification, the enamel desulfurization board used must work in an acidic medium environment, and its service life is not less than 50,000h. Desulfurization board needs to be coated with acid-resistant enamel frit, which has excellent acid resistance and can resist strong acid corrosion.

2. Good surface wear resistance

The Mohs hardness of the desulfurization plate porcelain enamel layer is about 6. During the working process, it must withstand the erosion of dust particles in the flue gas and must have good wear resistance.

3. Easy to clean

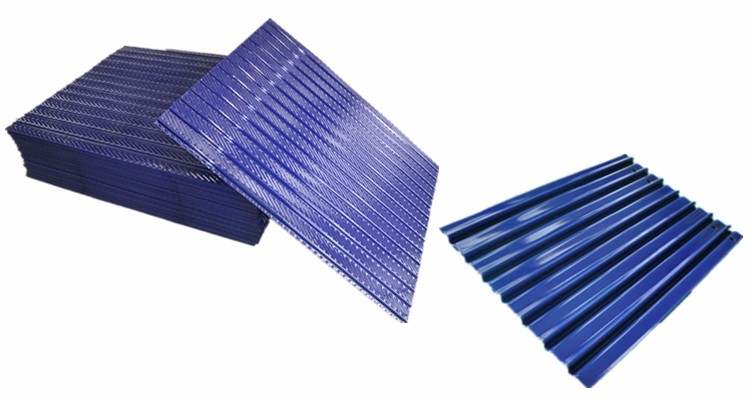

Enamel desulfurization board is a composite material made by coating a layer of desulfurization board enamel frit on the surface of decarburized cold-rolled steel plate and firing at high temperature. The good conductivity of the steel plate itself makes the heat transfer efficiency high for enamel desulfurization plate. The desulfurization board has a smooth surface, and has the characteristics of low air flow resistance and easy to clean during use.

4. Good temperature shock resistance performance

The desulfurization board enamel frit has a relatively high softening point, so it has good thermal stability, that is, the enamel desulfurization board is not prone to cracks on the porcelain enamel surface during repeated temperature changes.