Properties Essential For Steel Enamel Ground Coat

Steel enamel ground coat in addition to good dense ability, but also must have the following characteristics.

2, The firing range of the ground coat is usually around 60°C. The firing amplitude of the ground coat mainly depends on the chemical composition of the ground coat. High temperature, low temperature two in one or high temperature, medium temperature, low temperature three in one ground coat firing range will be greater than the firing range of any single ground coat.

3, The ground coat melt should have good ability to infiltrate metal, surface tension should be small, viscosity should be low, mobility should be good, and can dissolve a large number of iron oxide on the surface of steel substrate, so that the ground coat and metal combined firmly.

The ability of the ground coat melt infiltration metal, mainly depends on the content of B2O3 and other oxides.

4, The ground coat should be compatible with the expansion coefficient of metal. ground coat expansion coefficient 3α for (280 ~ 320) x 10-7 / K. Enamel products firing, the ground coat and metal blank firmly together, such as the expansion coefficient of the two do not fit, will produce porcelain layer crack or fall off. Because the compressive strength of enamel glaze than tensile strength, so the expansion coefficient of the ground coat should be smaller than the expansion coefficient of the metal blank, so that the enamel products firing cooling porcelain layer by compressive stress, rather than by tensile stress.

5, The ground coat must also have good elasticity and compressive strength.

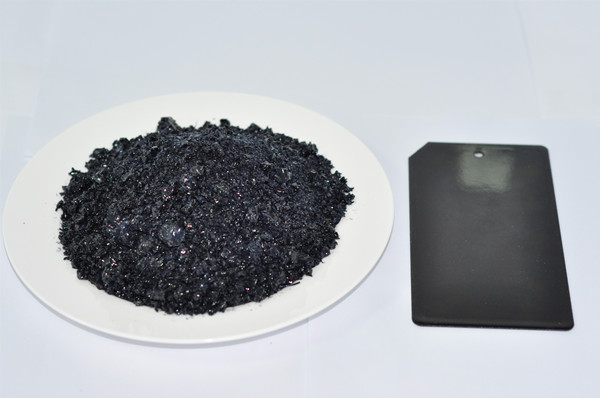

To obtain the above characteristics, mainly depends on the content of various chemical compositions in the formulation of the enamel ground coat for steel plate. The chemical composition of ordinary daily use steel plate enamel ground coat formula.

SiO2 45~57%

K2O + Na2O 15~20%

CaF2 5~10%

Al2O3 5~7%

B2O3 5~15%

CoO+NiO+Sb2O3 0.5~3%

Usually, the ratio of SiO2 to K2O+Na2O in the formula determines the firing temperature of steel plate enamel ground coat, 2.25~2.5 for low temperature steel plate enamel base glaze and 2.7~3 for high temperature steel plate enamel ground coat.

SiO2, Al2O3 content in the formula increases, the firing temperature of the ground coat increases, and can enhance the mechanical strength of the steel plate enamel ground coat; B2O3 content increases, the firing of the ground coat melt dissolution of FeO, the iron billet wetting ability is enhanced, thus the elasticity is beneficial, and can reduce the firing temperature of the ground coat; K2O to improve the elasticity of the ground coat is beneficial; CaF2 can increase the high-temperature fluidity of the ground coat, but Excess will make the porcelain surface of the ground coat produce pinholes and bubbles, and too little content will produce scorched spots.