Preparation Process of Enamel Slurry

The main purpose of enamel grinding is to separately grind enamel frit into powder or mix the frit with milling additives and solvents etc. Then pulverize it, make it granules with fine particles and slurry with uniform distribution to meet various coating requirements. For wet process, it is mainly made into a suspension liquid, that is, a silicate suspension system. For dry process, it is mainly made into enamel powder.

Enamel grinding methods include dry and wet process. For ground coat and cover coat of daily enamel cookware, industrial acid-resistant ground coat and cast iron ground coat, they are mostly wet-dipped or sprayed, so wet-grinding is used; While industrial acid-resistant ground coat and cast iron cover coat of dry process are dry ground, because industrial acid-resistant ground coat and cast iron cover coat of dry process are very different from the thin-plate enamel products. Industrial acid-resistant enamel requires the enamel surface to be extremely dense. Therefore, the amount of clay added is very small, generally 3% to 3.5%. The levitation of the enamel slurry is poor, so the dry powder is used before spraying. Cast iron cover coat, especially cast iron bathtub, as the dry enamel powder is scattered to the red hot cast iron, so the frit must be dry ground into powder.

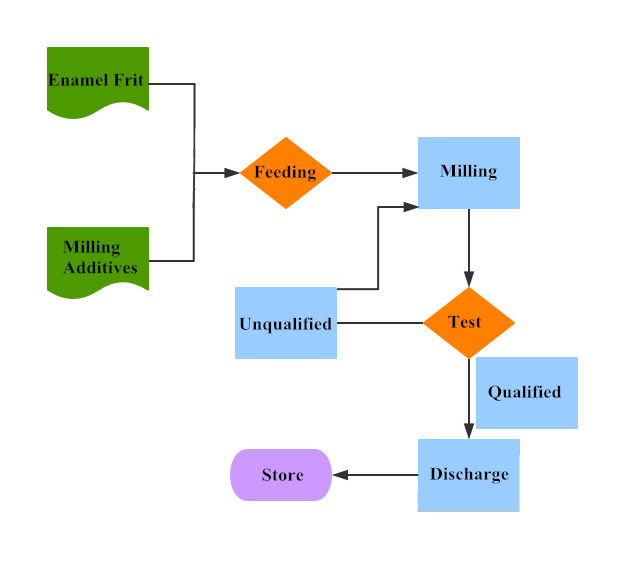

The process of wet enamel grinding is shown in the figure below:

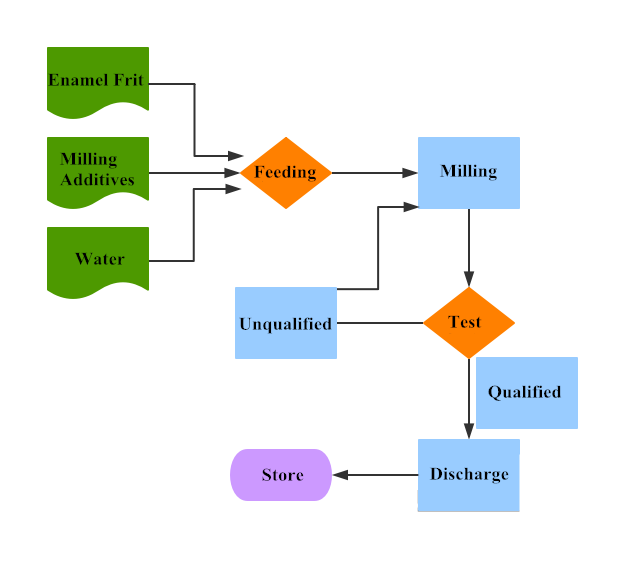

The process of dry enamel grinding is shown in the figure below: