Porcelain Enamel Heat Exchange Elements

Enamel heat exchange elements are divided into two types: plate type and tube type, which are mainly used in boiler equipment in industrial fields such as thermal power generation, petroleum, and chemical industries. Plate-type enamel heat exchange elements are mainly used for air preheaters, flue gas desulfurization and denitrification, and tube-type enamel heat exchange elements are mainly used for air preheating vessels.

Characteristics of enamel heat exchange elements:

1. High heat transfer efficiency, low air flow resistance, easy to clean

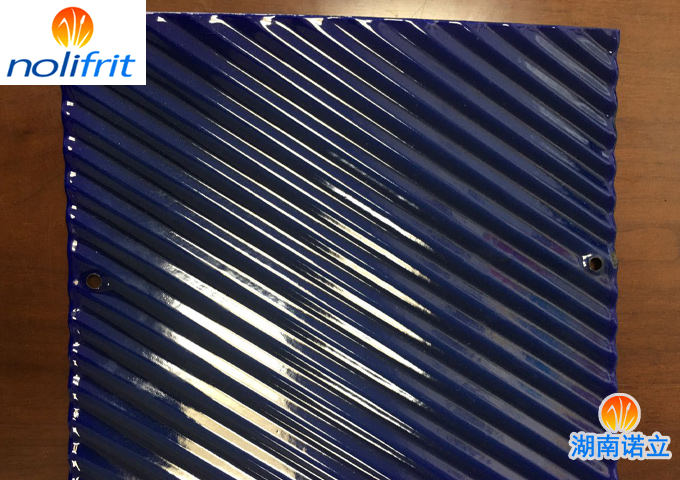

The enamel heat exchange element is a composite material formed by coating a layer of enamel frit on the surface of a decarburized cold-rolled steel plate and firing it at a high temperature. The good conductivity of the steel plate itself makes the heat transfer efficiency of the enamel heat exchange element high. The surface of the enamel heat exchange element is smooth, and it has the characteristics of low air flow resistance and easy cleaning during use.

2. Excellent corrosion resistance

Whether it is flue gas desulfurization or denitrification, all enamel heat exchange elements must work in an acidic medium environment, and their service life is not less than 50,000h.

3. Good surface wear resistance

The Mohs hardness of the porcelain layer of the enamel heat exchange element is about 6. During the working process, it must withstand the erosion of the dust particles in the flue gas, and it must have good wear resistance.

4. Good temperature and sudden change performance

Since the acid-resistant enamel used in the enamel heat exchange element has a relatively high softening point, it has good thermal stability, that is, the enamel heat exchange element is not prone to cracks on the porcelain surface during repeated temperature changes.

5. Good stress resistance

The plate-type enamel heat exchange element is to pack multiple sets of corrugated plates and positioning plates into a warehouse box, compact with a certain pressure, and then weld the warehouse box into a whole. During assembly and welding, cracks on the surface of the porcelain layer should not occur, and the porcelain should not be dropped. Therefore, the plate enamel heat exchange element must have good pressure resistance.