Nolifrit Solution For Irregular Beading Enamel

Irregular Beading Enamel is a common defect in enamel coating industry. It often occurs in cover coated enamelware with edge or corner. When the enamel is applied by dipping or spray, there will often be some edge or corner on which the enamel is not appropriately coated, the enamel layer here is usually too thin or too thick, both two situations are easily cause enamel chipping, thus result in the irregular beading.

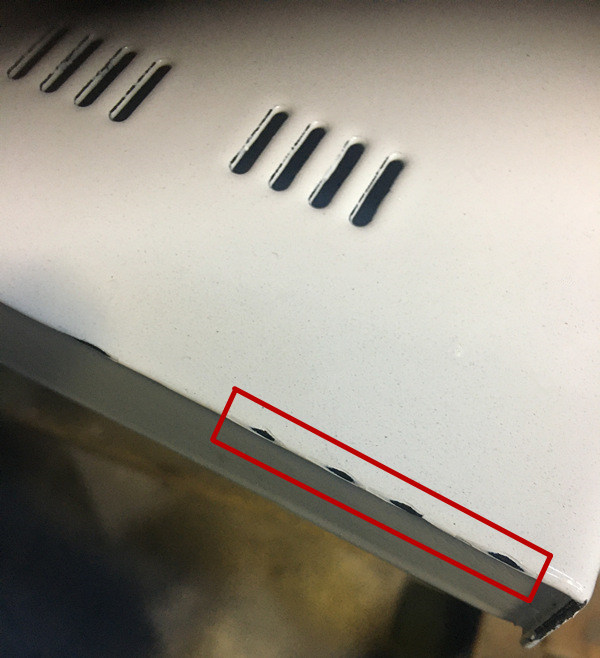

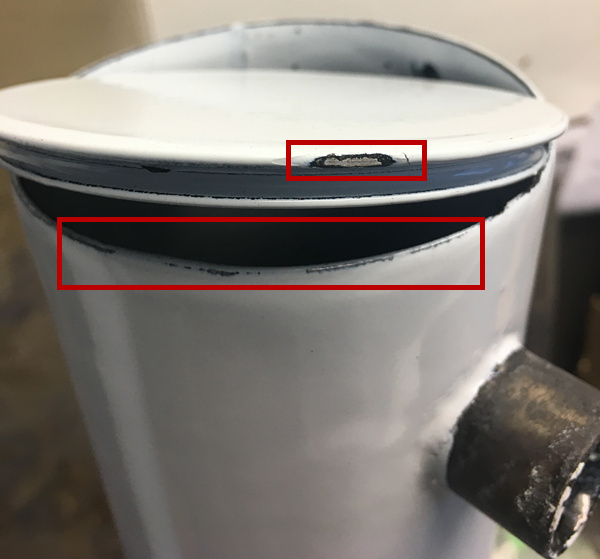

One of our customer are facing this problem and ask for our help about this. They are using our white cover coat frit coated on their enamel buckets, their ground coat is also from us, and they coat it perfectly without any defects, but when the white cover coat is coated on ground coat, the problem comes out, the edge of the ware is easily chipped off, and the ground coat and steel substrate is exposed.

Nolifrit advices for irregular beading defect:

1, Before coating the enamel layer on the metal body, special attention should be paid on the edge and corners, the edge and corner should be ground smoothly, make sure the coating thickness is not too thin or too thick than other areas of the enamelware.

2, The essential cause of the defect is due to the expansion coefficient of the edge and corner is different than other areas, after firing and cooling, the edge and corner shrank in different degree than other areas of metal body, which will cause the enamel chipping. So we can apply a tinned edge on the ware, it can be stainless steel or special edge enamel like blue edge frit, with higher expansion coefficient, the edge enamel will not easily chipped off even under very harsh condition.