Nolifrit Fish Scale Resistant Enamel Frit

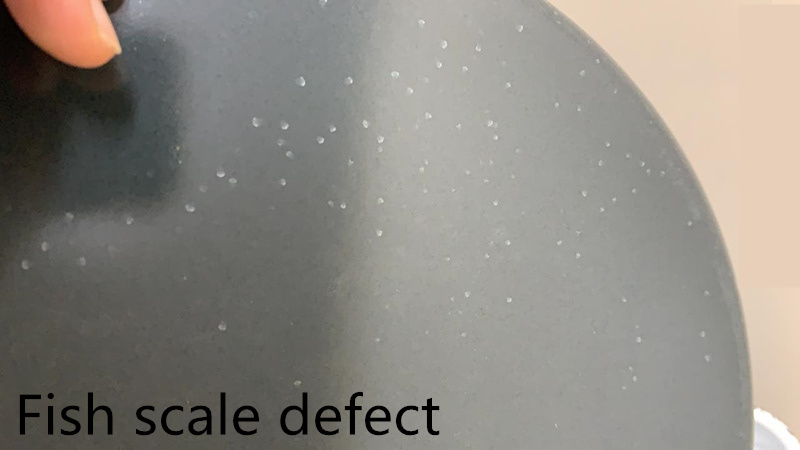

Fish Scale enamel is a common defect known to all enamel industry. Although there are several test methods for detecting the fish scale defect, there is always the possibility of encountering this problem, because not every enamel factories have strict process control, and enamel process is complicated, as long as there is a mistake in one of the links, it may cause fish scale problem..

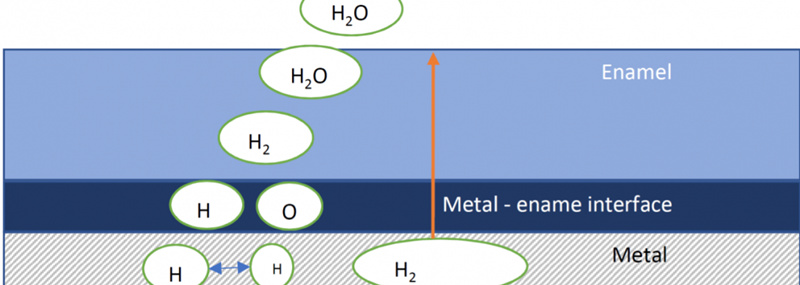

Considering its general structure, the fish scale is caused by the amount of carbon in the steel sheet, and after the enamel application process is finished, it can sometimes appear on the sheet surface after several hours, or even one week.

As a result of the studies carried out in our R&D center, Nolifrit have reached an enamel solution that can reduce the possibility of fish scale defect even on very thick and low quality steel plate.

One of our customers tried our fish scale resistant enamel frit, and they finally overcame fish scale on their enamel cookware. They are using normal cold rolled steel plate, as they can’t afford the high cost of enamel grade steel. Here we not only help them to solve the fish scale problem, but also reduce their production cost on steel plate.

Before use our fish scale resistant enamel frit ↓↓↓

After our fish scale resistant enamel frit is applied ↓↓↓

Even tough this enamel is still under development, we still continue our efforts to solve one of the biggest problems of the enamel coating industry.