Nolifrit Detail Explanation on Enamel Pretreatment

Enamel pretreatment refers to the reasonable treatment of the surface of the metal body to be coated with enamel frit to maintain the maximum cleanliness and roughness. Enamel pretreatment is an important guarantee for smooth firing and it is of great significance for improving product quality.

The main function of metal enamel pretreatment is twofold:

1. Remove the oil dirt, rust, and oxide on the surface of the metal body, and make it no longer rust in a short time, to obtain a surface that meets the requirements of enamel quality.

2. Due to the deep processing of the metal body, the internal grain structure is deformed and there are residual stresses, the annealing treatment is helpful to eliminate the stress inside the iron body and remove some surface carbon, thereby reducing the defects due to the body deformation caused by stress like black lines, broken edges, bubbles and pinholes. Iron body with less severe residual stress generally do not require annealing. Annealing of cast iron products is recommended because the carbon content of cast iron is higher than that of steel plates. Annealing can significantly reduce the defects caused by carbon dioxide gas generated by carbon oxidation during enamel firing.

The quality of the enamel pretreatment of the metal body has a direct impact on the quality of the enamel product. If the treated metal body has oil stains and rust marks, it will make it difficult to coat the steel enamel ground coat or fall off after drying. And cause shrinkage when firing, even cause defects such as air bubbles, pinholes, and poor adhesion.

The methods of metal enamel pretreatment mainly include degreasing and pickling, burning oil pickling and burning oil sandblasting.

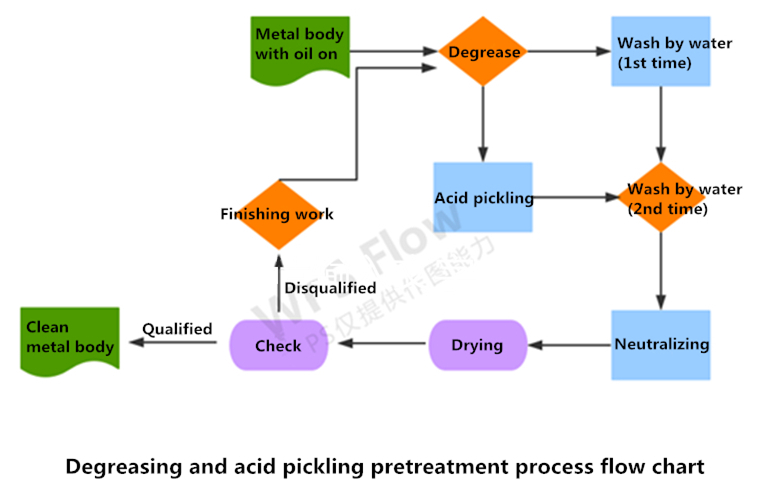

First, degreasing and pickling is a widely used surface treatment technology for metal materials in the enamel industry. There are two ways of operation: one is manual operation of intermittent transmission, and automatic operation of continuous transmission. Manual processes are being phased out with advances in production technology. The non-corrosive iron body can omit the pickling process, which is beneficial to improving the operating environment, improving production efficiency and reducing production costs. At the same time, people's awareness of environmental protection is getting stronger and stronger today. The state's control over the use of inorganic acids and the discharge of waste acids is becoming more and more stringent. Eliminating the pickling process can greatly reduce the environmental protection pressure of production enterprises. At present, domestic enamel companies are using pickling-free boards in large areas, which is also a product innovation made by steel mills in response to changes in market demand.

Second, the process of burning oil pickling

Generally, the metal body does not need to be burned with oil. Only when the metal is thick, the internal stress after rolling is serious, or the surface of the metal body has special oil greased on, the oil burning and pickling process is used. After the metal body burns with oil, the oxide skin will formed on the surface and it must be removed by pickling.

Third, the process of oil burning and sand blasting

This process is mainly used for thicker products such as industrial enamel reactors, enamel water heater liners, enamel pipes and other products. The oxide skin formed on the surface of the iron billet after burning oil must be removed by sandblasting.