Nolifrit Brief Analysis on Viscosity of Enamel

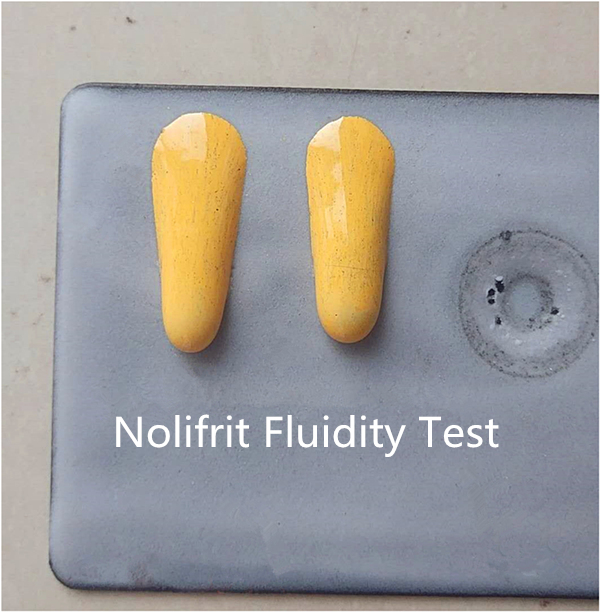

Viscosity is a measure of the resistance of a liquid to flow. The greater the viscosity, the smaller the fluidity, and the unit of viscosity is Pa•s.

Enamel frit is similar to glass and has no constant melting point. The solid enamel layer is gradually softened and converted into a melt under the condition of constant heating. Therefore, the viscosity of the enamel is continuously changed, and there is no numerical mutation. This is different from crystals. When the crystal is heated to the melting temperature, its viscosity changes abruptly.

In the first stage of enamelware firing, enamel powder layer decreases in viscosity with increasing temperature; in the later stage of firing, the enamelware gradually cools and the viscosity increases with decreasing temperature. When the viscosity reaches or exceeds 1012 Pa•s, the molten enamel layer becomes a solid enamel layer.

At a typical firing temperature, the enamel melt has a viscosity of 200 to 400 Pa•s.

The viscosity of the enamel depends mainly on the chemical composition of the enamel. The influence of the composition of the enamel on the viscosity is very complicated. The composition and content of the oxide are different, and the influence on the viscosity of the enamel is different in different temperature ranges.

Enamel frit manufacturer found that the introduction of monovalent alkali metal oxides, B2O3 and fluoride in the enamel can reduce the viscosity of the enamel melt; the introduction of SiO2, Al2O3, CaO, MgO, etc., makes the viscosity of the enamel melt increase. When the content of TiO2 in the formulation does not exceed 8%, the viscosity of the enamel melt is lowered; when the content exceeds 8%, the viscosity of the enamel melt is increased.

Milling additives like quartz, zirconium silicate, feldspar, titanium oxide, tin oxide, clay, etc., can not be completely dissolved in the enamel in short firing time and at lower temperature, so this makes viscosity of enamel melt improved.

The enamel with high viscosity is not conducive to the escape of gas in the enamel layer during firing, which increases the pores and bubbles of the enamel layer, and is not conducive to the flow of the enamel melt during firing, which tends to cause the fineness and gloss of the enamel surface to decrease. For enamel products requiring high-temperature firing, enamel with high viscosity is beneficial to improve the burning resistance and firing range of enamel products.