Nolifrit Anti Fishscale frit for Enamel Coating

The fishscale defect in the enamel coating on steel products is well known as an undesired phenomenon. The fishscale defect is caused by hydrogen gas pressure at the enamel-steel interface that causes the enamel to fracture. This problem limits enamellers to low carbon steel in order to avoid fishscale defects. The customers of frit producers often send many different types if steel and ask “is it possible to enamel such type of steel?” This demand has become critical as the hot water tank industry has grown. Consequently, this fact has required a solution for high carbon steel to be found.

Fishscale is a well-known defect in the porcelain enamel industry. Enamellers strictly control their steel to be defect free so they choose special quality steel. When the steel batch arrives, enamellers take samples from each steel coil and carry out initial tests for fishscale. Even with all these precautions, enamellers still face fishscale sometimes. This is mainly caused by variation with the steel coil. It has been seen that development of fishscale resistant enamel could work at least as an insurance mechanism but also could le t enamellers to use lower quality steels.

Fishscale is mainly caused by hydrogen itself. In practice, hydrogen is everywhere in the enameling operation. The main source of hydrogen is moisture in the air. The H2O penetrates the enamel and separates into oxygen and hydrogen. Oxygen is consumed in the adherence reaction, and atomic hydrogen diffuses inside the steel. Atomic hydrogen is too small to penetrate into the steel. hydrogen re-combine to form H2 gas. When the temperature is raised, the hydrogen solubility of steel also increases. This means that steel can absorb more H2 than its capacity. During cooling, hydrogen gas tends to go out from steel due to decreased solubility hydrogen release causes fishscale defects on the enamel surface. The intensity of fishscalling is directly linked with amount of water in the sys tem as well as the absorption capacity of steel.

In the enameling industry, cold rolled steel Is used with several specifications well known by steel producer. Many steel producer have enamel quality steel in their product line. The main requirement is the production method should be cold rolling and the carbon content of steel should be as low as possible. Several works have been carried out to overcome fishscale.

The fishscale phenomena is affected by both steel and enamel properties. It has been found that adding nickel addition to the enamel helps decrease fishscale. In the work, different enamel systems have been developed for different applications. The steel has 0.25% carbon content, and the result was proved with side by side application.

The main measures to avoid fishscale on enamel coating:

1. The choice of steel plate: Enamel steel is always the best choice, then cold rolled steel, hot rolled steel is most likely to have fishscale.

2. The surface treatment of steel plate: Try not use acid pickling, or use little acid pickling in very short time and use corrosion inhibitor when acid pickling.

3. For the ground coat: Choose the ground coat with suitable adherence.

4. For the milling additives: Use quartz, carbonate and quality clay in suitable amount.

5. For the firing process: Fire in reasonable temperature and time, make sure not to burn.

6. For the thick steel plate, only accept coating on single face.

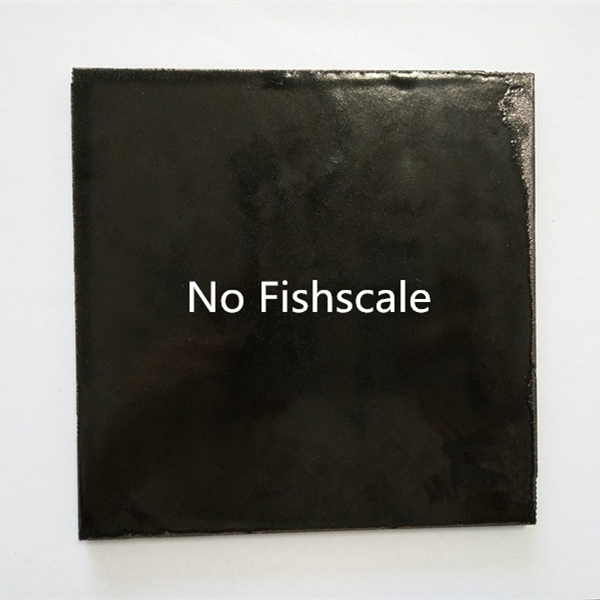

Hunan Noli Enamel Co.,Ltd has developed a Anti fishscal porcelain enamel frit 2466 to avoid the fishscale defect. It can be even applied in hot rolled steel and the effect can be acceptable.

Enamel coating mixed with 2466 : (Nolifrit)

Enamel coating with normal enamel frit: