Key Points of Enamel Batch Material Mixing

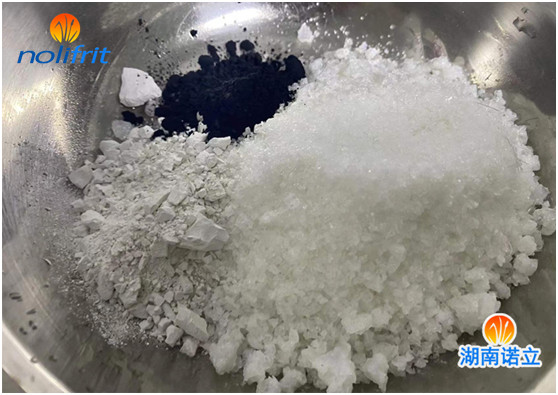

Enamel batch materials are mixed from various raw materials with different properties and functions. In order to allow the raw materials to fully play their role in the melting process and ensure that the melting reaction of the enamel is complete, in the mixing type of batching materials, each group must be evenly distributed to ensure the melting quality of the enamel.

There are two kinds of mixing methods: manual mixing and mechanical mixing.

(1) Manual mixing points:

1. The raw materials should be laid out in layers;

2. Refractory raw materials and Zhurong raw materials should be cross-mixed;

3. Sodium nitrate and metal antimony should be mixed first and then added;

4. Adhesion and coloring raw materials should be mixed with some borax or sodium carbonate first;

5. When mixing, it should be mixed back and forth twice, and twice in the sieve.

6. Feeding sequence: feldspar - fluorite - quartz - sodium fluorosilicate - sodium nitrate + metal antimony - borax - other raw materials.

(2) Key points of mechanical mixing:

1. Feeding should be done in order;

2. Sodium nitrate and metal antimony need to be mixed in advance;

3. The mixing machine should be dedicated to the special machine as much as possible. If one machine is used for multiple purposes, it should be shallow and then deep, from titanium to antimony;

4. If the color glaze is mixed, and then the white material is mixed, the shovel should be cleaned before use;

5. The mixing time should be kept for 10~15 minutes;

6. The powder that is qualified for the uniformity measurement should be melted as soon as possible to avoid agglomeration, delamination and impurity intrusion after being placed for too long;

7. Feeding sequence: borax - feldspar (half amount) - sodium carbonate, a small amount of raw materials - sodium nitrate + metal antimony (or dense, coloring raw materials) - fluorite, sodium fluorosilicate - feldspar (half amount )--quartz.

For the mixing of enamel ingredients, we need to pay attention to the following: First, the largest particle of the mixed powder must pass through 8 meshes; the mixing uniformity should reach more than 96%.