Introduction of Industrial Enamel Frit

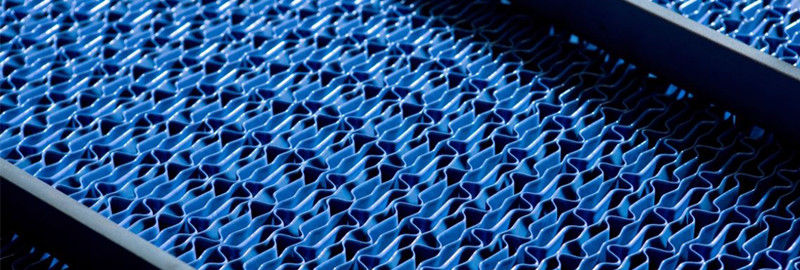

The industrial enamel products currently on the market are mainly enamel flat condensers, enamel pipes and accessories, enamel storage tanks, enamel tower sections, enamel reactors, enamel bolted tanks, etc. Industrial enamel frit are mostly used in chemical equipment. These equipment undergo chemical reactions under high temperature and high pressure conditions, and most of them are in contact with strong acid and strong alkali solutions.

Therefore, the characteristics of industrial enamel frit must have:

1. Good mechanical strength

2. Good thermal stability

3. Good acid and alkali resistance chemical stability

4. No bubbles, pores, burn and other defects during firing

5. The adhesion strength is better

Industrial enamel frit requires high chemical stability and thermal stability. Therefore, the content of SiO2 in the chemical formula is very high, generally around 65%, and some as high as 70%.

Industrial enamel frit requires high chemical stability and thermal stability. Therefore, the content of SiO2 in the chemical formula is very high, generally around 65%, and some as high as 70%.

It is difficult for industrial enamel frit to have excellent acid and alkali resistance at the same time. The introduction of ZrO2 in the formulation can improve the chemical stability of industrial enamel frit.

The special chemical composition and product structure of industrial enamel products require a relatively wide firing range of industrial enamel frits. Therefore, composite ground coat are used, that is, two or more ground coat frits are matched in a certain proportion and ground at the same time. A large amount of quartz is added to form an industrial enamel composite ground coat.

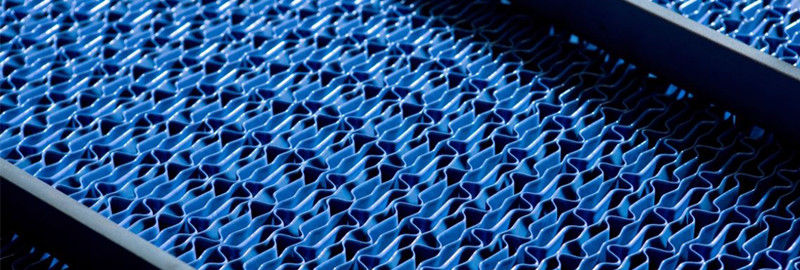

Therefore, the characteristics of industrial enamel frit must have:

1. Good mechanical strength

2. Good thermal stability

3. Good acid and alkali resistance chemical stability

4. No bubbles, pores, burn and other defects during firing

5. The adhesion strength is better

It is difficult for industrial enamel frit to have excellent acid and alkali resistance at the same time. The introduction of ZrO2 in the formulation can improve the chemical stability of industrial enamel frit.

The special chemical composition and product structure of industrial enamel products require a relatively wide firing range of industrial enamel frits. Therefore, composite ground coat are used, that is, two or more ground coat frits are matched in a certain proportion and ground at the same time. A large amount of quartz is added to form an industrial enamel composite ground coat.