How To Solve Enamel Chipping-Off And Fish-Scale

Enamel chipping-off and fish-scale are common defects of enamel products, which refer to the internal and external stress on the porcelain surface after the enamel products are fired. If the enamel finished product is de-ceramic, you can start to analyze it from the following reasons.

(1) De-Porcelain: The enamel falls off

Cause Analysis:

1. Devitrification due to severe cracks; 2. The ground coat is too thin on the sides, handles, feet, and bottom, and the firing temperature is high; 3. The cover coat is too thick and the firing is insufficient.

Solution:

1. Appropriately increase the curvature radius of the side, handle, foot and bottom; 2. Adjust the bulk density of the enamel slurry to avoid local coating too thin or too thick.

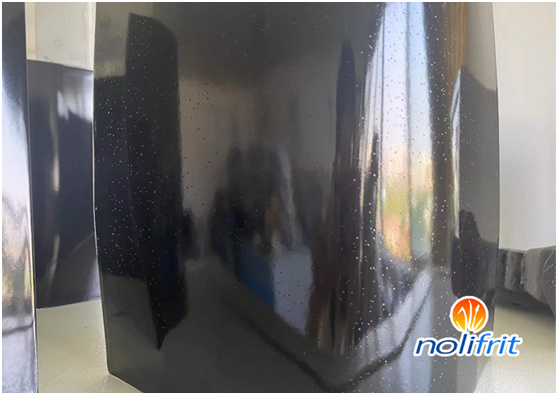

(2) Scale explosion: The porcelain surface is scaly and loses the porcelain (some appear after firing, and some appear in a week or more)

Reason analysis: 1. The content of C.S.P.Si in the thin steel plate is high; 2. The acid concentration is high, and the pickling time is long; 3. The clay is of poor quality and there are many impurities; 4. The furnace temperature is high, and the ground coat is partially scorched.

Solution: 1. Choose a high-quality steel plate suitable for enamel; 2. The acid concentration should not be too high. The pickling time should be appropriate; 3. Choose high-quality clay; 4. Use hard and soft mixed primer. Grind and add about 10% calcined quartz, and the ground coat firing furnace temperature should not be too high to avoid local scorching.

Nolifrit is a supplier of enamel frits and inorganic pigments, providing customers with free technical services. If you have related needs, please contact us!