How To Prevent Fish-scale Defect

Fish-scale is one of the defects that are very easy to encounter in enamel products. It has various causes and makes people deeply troubled. At present, some experienced enamel frit manufacturers can provide customers with technical solutions to prevent or solve the problem of fish-scale problem. This article will explain in detail to you.

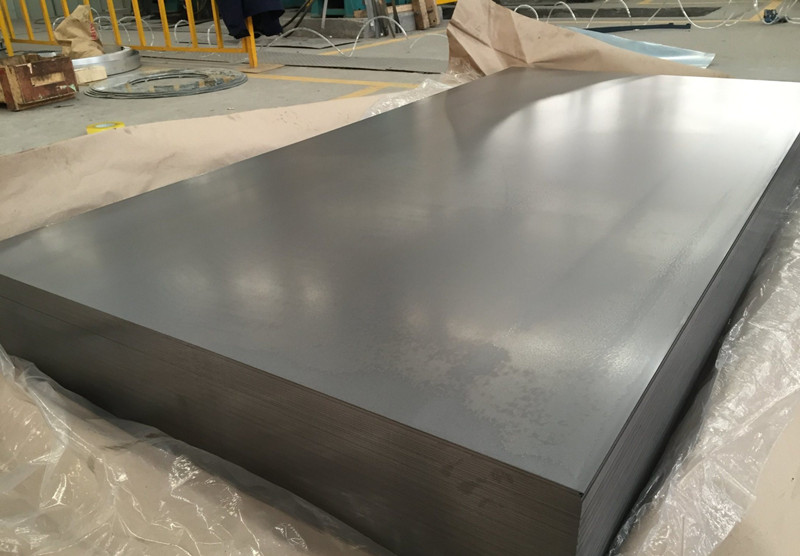

The generation of enamel fish-scale is mainly caused by the hydrogen content of the steel plate. There are many sources of hydrogen, and it is generally believed that there are the following three: one is the dissolved hydrogen of steel, the hydrogen content of steel after refining treatment is relatively low. In particular, the hydrogen content of the annealed steel sheet will be lower, so this part of the hydrogen is very weak; the other two ways are the hydrogen produced during the pickling of the steel body pretreatment and the enamel firing process.

Through the above summary and analysis, in order to prevent or solve the problem of fish-scale, it is mainly necessary to solve the above three aspects of hydrogen sources. Enamel frit manufacturer Nolifrit have proved through a large number of experiments that if the steel plate is of good quality (insensitive to fish-scale), it will be unlikely for enamel products to have fish-scale defect. But if the steel plate is of poor quality (sensitive to fish-scale), then no matter how the external conditions are met the demand for enamel products, it cannot restrain the occurrence of fish-scale. Therefore, first of all, everyone should pay attention to the selection of steel plates and choose special enamel grade steel plates that are not easy to have fish-scale.

In addition, domestic professional enamel frit factories have developed anti-fishscale enamel frit for the defect. This enamel frit can effectively reduce the probability of fish-scale defect of enamel products to prevent product with fish-scale problem. Of course, anti fish-scale agents can also be added to suppress the fish-scale of the enamel, but the amount of addition needs to be controlled. Excessive amounts will easily cause bad enamel surface.

To prevent the fish-scale of the product, the enamel frit manufacturer recommends that we mainly start with the steel plate. A good steel plate can be used once and for all to avoid many enamel product defects. The anti-fishscale enamel frit and the addition of anti-fishscale agents are just a means of restraint. It can reduce the risk of fish-scale defect, but it is not a perfectly method.