How to make stainless steel enamel?

Stainless steel has many excellent characteristics and is widely used in cooking utensils, building decoration, household goods, and other occasions. However, under high-temperature conditions, the grain boundaries of stainless steel are susceptible to corrosion by hot corrosive gases, which shortens life. The stainless steel enamel developed in recent years has strong corrosion resistance and good energy-saving effects. This article Nolifrit combines the choice of stainless steel material and enamel frit to analyze how to make stainless steel enamel.

1.Selection and treatment of stainless steel

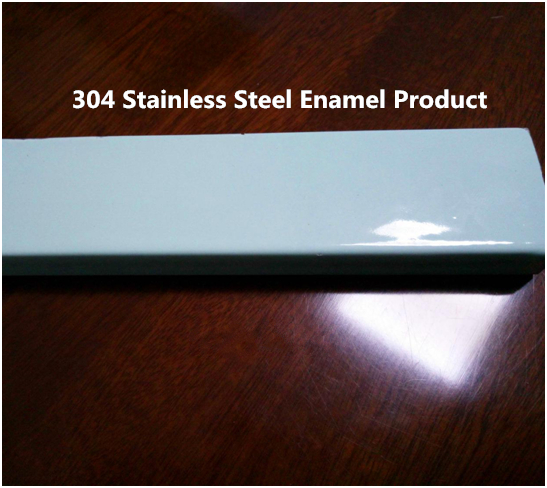

When selecting stainless steel, you should choose a stainless steel plate with high corrosion resistance, high mechanical strength, low impurity content, and no defects. We recommend using 304 stainless steel as the material. If it is a processed stainless steel body, the arc at the turn is as smooth as possible. If the radius of curvature is too small, it will cause excessive internal stress at the corners, which will increase the chance of a cold explosion of enamel. In order to make coating easier, the surface needs to be degreased and de-rusted. It is recommended to use the surface treatment method of pre-firing and sandblasting. A certain depth must be reached during the blasting to facilitate the adhesion of the enamel layer.

2. Selection of enamel frit

The coating of stainless steel enamel products can be done in two passes ( ground coat and cover coat), or only enamel cover coat. This should be selected according to actual needs. The two passes are used, because a special base glaze dedicated to stainless steel enamel is selected, which is stronger than the ordinary base glaze. The adhesion of the enamel layer will be better, which is suitable for stainless steel enamel products with certain strength requirements. For stainless steel enamel products that only care about the appearance, they can use only enamel cover coat. Choose titanium white frit, titanium lake blue frit, titanium fruit green frit to directly achieve the desired color and appearance effect.

3. Burning

After the frit and mill additives are ball-milled, the slip can be uniformly coated on the surface of the stainless steel body by spray lining or manual coating. If the surface area of the product is large, it is recommended to use a spray gun for spraying, so that the product surface will be more delicate and even. After coating and lining, the product is placed near a heat source such as an oven to be dried. After thoroughly drying the moisture, it can be sintered.

After enamel, the performance of stainless steel can be greatly improved. According to relevant data, enamel-coated stainless steel products are quite resistant to boiling water, alkali and thermal stability. The sample was immersed in a 5% sodium carbonate solution, and the liquid temperature was maintained at 80 ± 5 ° C for 20 minutes. Then the sample was removed and dried, and the porcelain surface did not lose its original gloss; The sample was placed in an oven and heated to 200 degrees. After being taken out, the sample was quenched with water, and the experiment was repeated three times without any cracking. Stainless steel enamel has good adhesion, smooth porcelain surface, and excellent corrosion resistance, which fully shows that stainless steel is suitable for more fields after being coated with enamel frit.

Related Searches:

Enamel coated stainless steel

Stainless steel enamel cookware

Enamel on stainless steel

Stainless steel enamel pots

Stainless steel enamel pans

Stainless steel enamel bowls

Enamel stainless steel utensils

Enamel stainless steel bakeware

Enamel stainless steel teapots

Stainless steel enamel dishes

Stainless steel enamel mugs

Stainless steel enamel plates

Enamel stainless steel kettles

Stainless steel enamel roasting pans

Stainless steel enamel skillets

Enamel stainless steel frying pans

Stainless steel enamel saucepans

Enamel coated steel durability

Enamel steel heat retention

Enamel stainless steel non-stick

Enamel steel corrosion resistance

Enamel stainless steel versatility

Enamel stainless steel heat conductivity

Stainless steel enamel weight

Enamel steel cookware benefits

Enamel steel kitchenware

Enamel steel cleaning ease

Stainless steel enamel surface

Enamel stainless steel colors

Enamel stainless steel safety

Stainless steel enamel durability

Enamel stainless steel aesthetics

Stainless steel enamel maintenance

Enamel stainless steel thermal efficiency

Enamel coated steel safety

Enamel steel cookware performance

Stainless steel enamel interior

Stainless steel enamel exterior

Enamel stainless steel oven safe

Enamel steel boiling capacity

Enamel stainless steel induction compatible

Enamel stainless steel grilling

Enamel stainless steel sustainability

Enamel stainless steel eco-friendly

Stainless steel enamel market trends