How Enamel Heat Exchanger Manufacturers Should Select Enamel Frits to Win the Market

In the global energy and environmental protection sectors, enamel heat exchangers have become the preferred choice in various industries such as thermal power, petrochemicals, pharmaceuticals, and food, due to their efficiency, corrosion resistance, and long lifespan. For manufacturers of enamel heat exchangers, selecting high-quality enamel frits is a crucial step in ensuring product quality and enhancing market competitiveness. This article briefly introduces how enamel heat exchanger manufacturers should choose suitable enamel frits.

1. Understand Market Demand and Product Characteristics

When selecting enamel frits, manufacturers of enamel heat exchangers must first clarify the specific needs of their target market. For example, the thermal power industry requires enamel layers to have excellent high-temperature and erosion resistance, while the petrochemical industry places greater emphasis on corrosion resistance. Based on these demands, enamel manufacturers should choose frits that match these requirements to ensure product suitability.

2. Focus on the Performance and Quality of Enamel Glazes

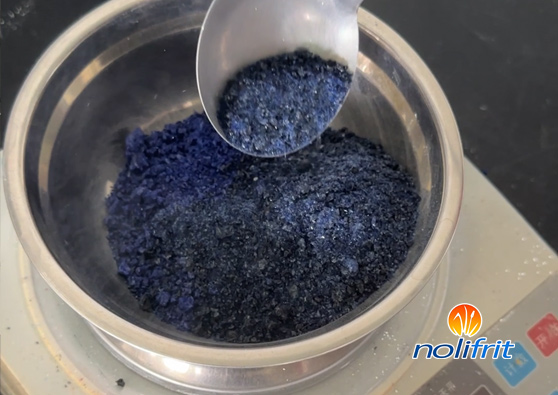

The performance of enamel frits directly determines the lifespan and performance of enamel heat exchangers. High-quality enamel glazes should exhibit good opacity, glossiness, a refined ceramic surface, and resistance to acids, bases, water, and heat. Additionally, the thermal expansion coefficient of the enamel frit should be compatible with the ground coat frit to ensure that no cracks or peeling occur during the firing process due to stress differences.

3. Choose Mature Formulas and Technical Solutions

The process of determining the formula for enamel frits is complex, requiring multiple stages of ingredient mixing, melting, ball milling, testing, and performance adjustments. Therefore, when selecting frits, enamel manufacturers should prioritize suppliers that have mature formulas and technical solutions. This not only ensures a higher product qualification rate and reduces defects but also lowers production costs and improves efficiency.

4. Emphasize Sampling and Testing

Before making a formal purchase, manufacturers of enamel heat exchangers should communicate thoroughly with enamel frits suppliers and request samples. Through rigorous testing, the performance of the enamel frit can be validated to meet expectations, thereby avoiding quality issues during subsequent production.

5. Establish Long-term Cooperative Relationships

High-quality enamel frit suppliers are crucial for ensuring product quality and market competitiveness. Foreign manufacturers of enamel heat exchangers should establish stable, long-term partnerships with suppliers to collaboratively engage in technological research and product innovation, continuously enhancing market competitiveness.

In summary, foreign manufacturers of enamel heat exchangers should take into account various factors such as market demand, product characteristics, performance quality, formula technology, sampling and testing, as well as cooperative relationships when selecting enamel frits. Only by purchasing high-quality enamel frits can they ensure product quality, win the market, and promote sustainable development of the enterprise.