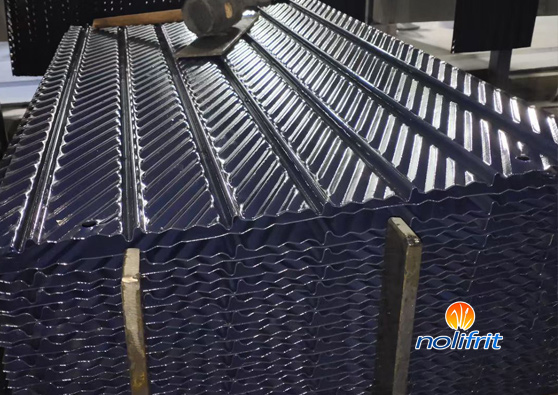

How Enamel Corrugated sheet Manufacturers Choose Enamel Coating Materials

In the production process of enamel corrugated sheet, the selection of enamel coating material is crucial. The enamel coating determines not only the appearance quality of the product but also directly affects the durability and competitiveness of the product in the market. How can enamel corrugated plate manufacturers choose the appropriate coating material? The following factors are key considerations:

Firstly, enamel coating material must be compatible with the production process and material of their own products. Different enamel corrugated plate manufacturers may have different production processes and sheet metal materials. Therefore, when choosing the coating material, it is necessary to ensure that the coating material can perfectly blend with their own products to achieve the best enamel effect.

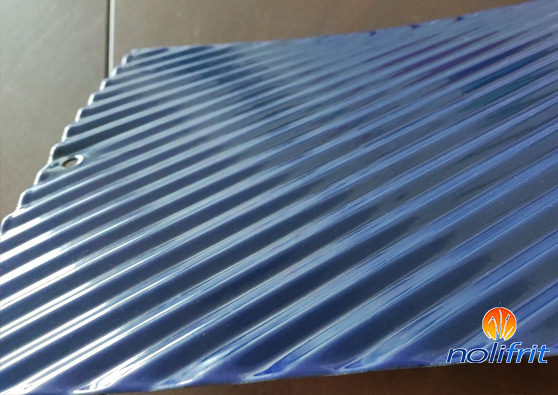

Secondly, the acid resistance of the coating is an important indicator that cannot be ignored when choosing the enamel coating. In the process of using enamel corrugated sheet, it may come into contact with various acidic substances. If the acid resistance of the coating is poor, it will cause surface corrosion, discoloration, and other problems, seriously affecting the service life and beauty of the product. Therefore, it is crucial to choose enamel coating material with excellent acid resistance.

Of course, cost is also one of the factors that manufacturers need to consider when choosing the coating material. Reasonably controlling the cost under the premise of ensuring product quality helps to improve product competitiveness in the market. However, this does not mean pursuing low prices blindly but finding enamel coating materials with the highest cost-effectiveness while ensuring quality.

In this regard, NOLIFRIT is undoubtedly a reliable partner. NOLIFRIT can customize an exclusive porcelain enamel formula based on the specific needs of enamel corrugated plate manufacturers to ensure that the coating material perfectly adapts to the product. At the same time, NOLIFRIT's acid-resistant enamel coating has an A++ level of acid resistance, which can effectively resist the erosion of various acidic substances and protect the surface of the product from damage. In addition, the cost-effectiveness of NOLIFRIT's coating material is also very high, which can help enamel corrugated board manufacturers to reasonably control costs while ensuring product quality.

In summary, choosing NOLIFRIT is a wise choice for enamel corrugated plate manufacturers to improve product quality and enhance market competitiveness. If you also have relevant needs, please feel free to contact us!