How Elements in Steel Affect Enamel Adhesion

The reaction between the enamel steel plate and the enamel frit forms an adhesive layer. By comparing the alloy components present in steel sheets, it is considered that high-alloy steel sheets (iron content: 98.6%, mass ratio) can be enameled as easily as low-alloy steel sheets (iron content: 99.7%, mass ratio). However, the proportion of alloying elements that can modify certain properties of the steel sheet is very important for the steel's ability to be enameled, such as resistance to spalling (by silicon or carbon) or subsequent corrosion protection by phosphating processes.

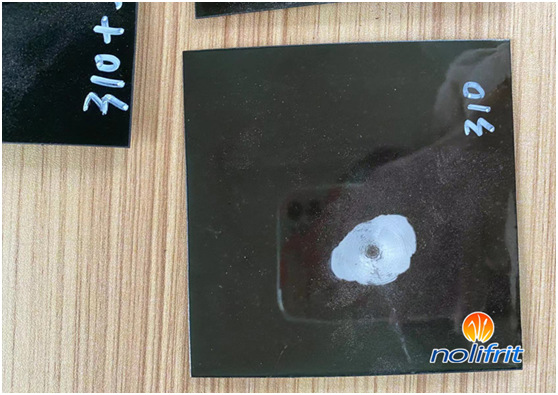

A basic prerequisite for successful enamelling is the formation of a new iron oxide layer on the steel surface during refiring and the subsequent dissolution of FeO in the enamel melt. Supersaturation leads to the precipitation of Fe-Cu-Co alloys, which attach to the newly formed iron surface to achieve a mechanical interlocking effect. There is a characteristic curve of Fe concentration gradient in the enamel layer. This Fe concentration gradient ensures an increased number of chemical bonds at the metal-enamel interface in the form of Fe-O-Si bridges.

If it is a hot-rolled steel plate, the existing oxide layer on the surface of the steel plate must be removed before glazing, otherwise it will cause poor adhesion.