Function of Colorants In Enamel Frit Raw Materials

The raw materials of enamel frit mainly come from minerals and rocks. clay and chemicals. The raw materials of enamel frit can be divided into refractories, fluxes, opalescent agents, colorants, electrolytes and suspending agents according to their functions. Colorants such as cobalt oxide, copper oxide, iron oxide, nickel oxide and other metal oxides are used to improve The adhesion of the frit. The enamel colorant and the basic enamel melt with each other, and the enamel frit will be colored with the special color of metal ions. Some colorants are in the form of gel or suspension in the enamel. Such suspended particles scatter or absorb light to show color. .

There are two ways to use colorants, one is to melt them together with other enamel raw materials to make a frit, and the other is to add them to the basic enamel in the form of grinding and grinding additives.

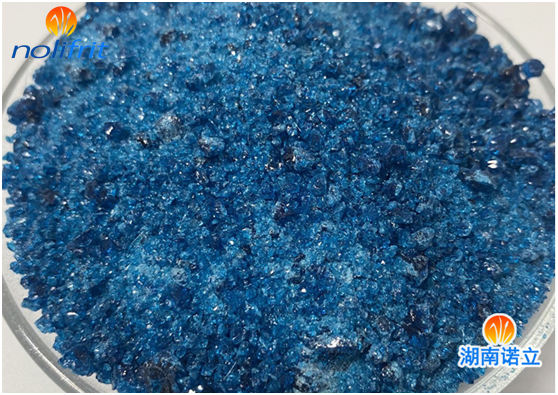

(1) Cobalt oxide: Cobalt oxide is not only a colorant, but also a raw material for improving the adhesion performance of enamel ground coat, and its dosage is 0.3~0.6%. Adding 0.002% cobalt oxide to the ingredients can get a clear blue color. If cobalt oxide and manganese, copper, iron, nickel and other oxides are combined, other different colors will be produced;

(2) Copper oxide: There are two kinds of copper oxide, CuO and Cu2O. CuO makes the enamel blue, and Cu2O makes it red. Copper oxide is mixed with cobalt oxide to give a cyan color, and chromium oxide is mixed to give a green color.

(3) Nickel oxide: the same as colorant and primer adhesive. It is reddish-purple in potassium-containing enamel and yellow-green in sodium-containing enamel.

Insensitive to coloration, it is often used in combination with other colorants. It is brown when used alone, and black or dark brown when combined wit