Firing Instructions for

Glossy, Plain and Matt Cast Iron Enamel

For the firing of wet cast iron enamel, the firing time needs to be prolonged due to the large volume of the object, but the firing temperature must be lowered in order to prevent the enamel glaze from boiling excessively. Wet enamel will boil in the initial stage of firing, but the boiling will stop in the later stage and a smooth film will be formed. The gas that promotes the boiling may come from the decomposition of clay, from the gas contained in the casting, or from the reaction between the enamel and the iron.

The body of dry cast iron enamel is larger, and the firing temperature should rise slowly, which can usually be divided into two stages. The object is heated only to bright red during the preheating stage, and then moved to the firing furnace (840~925°C). When the casting reaches the temperature of the firing furnace, it is quickly removed and sprinkled with glazing powder and placed back in the furnace until the enamel melts to a smooth finish.

Generally, cast iron enamel can be divided into 3 types according to the gloss, as follows:

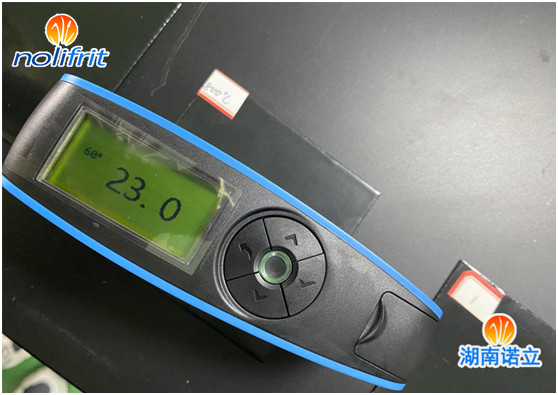

A. Glossy: Gloss: 60~85°. (High brightness above 85°)

Heat resistance test: After being fired at 450°C for 30 minutes, the enamel will not change when placed in water at room temperature.

B. Plain: Gloss: 30~60°.

Heat resistance test: After being fired at 450°C for 30 minutes, the enamel will not change when placed in water at room temperature.

C. Matte: Gloss: below 30°.

Heat resistance test: After being fired at 500℃ for 30 minutes, the enamel will not change when placed in water at room temperature.