Enamel Without Ground Coat?

Detailed Explanation Of Direct-on Enamel

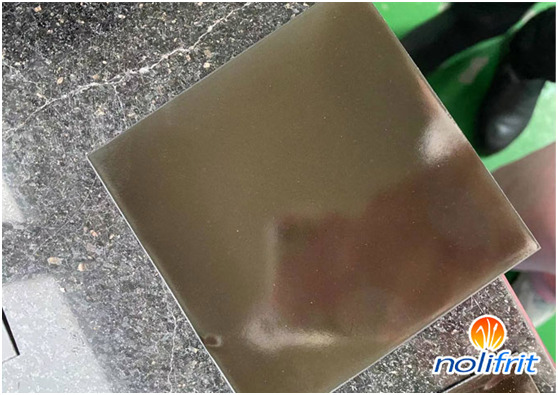

Enamel without ground coat refers to the direct application of white devitrified titanium enamel to the steel plate without firing a layer of ground coat in the middle, which can save raw materials and shorten the process of enamel coating. This is also called direct-on enamel.

The enamel without ground coat is especially suitable for enamel castings with simple structures, which are not subject to high mechanical force and high heat during use. The most suitable steel for direct-on enamel is zero carbon steel containing a small amount of titanium. In recent years, a special steel has been produced, with a carbon content of 0.0001~0.0003%, and has undergone special heat treatment. This prevents the formation of bubbles, burnt and other defects when applying bottomless enamel.

Titanium steel is still too expensive to be used in mass production. Although zero-carbon steel is a little more expensive than standard steel, it is very cost-effective in terms of the reduction in the amount of enamel frit and the simplified procedures for one-time coating.

As for the basic technical difference of enamel without ground coat, more care must be taken when equipping the metal surface. Because the ground coat contains cobalt when firing, due to the reaction to provide bonding force, if the enamel without ground coat is used, on the one hand, it will give the metal surface a certain degree of brittleness; Oxidation, and improve the binding force. When enamel without ground coat, the firing temperature should be increased by 20~40℃.

Nolifrit is a supplier of enamel frits and inorganic pigments, providing customers with one-stop service, if you have any questions, please contact us!