Enamel Defects - Quick Troubleshooting Tips to Avoid Mistakes

During the enamel production process, problems such as glaze defects and poor adhesion often impact production efficiency and product quality. As a manufacturer deeply involved in the glaze field, we've developed a practical problem-solving process through our technical support services. Today, we're sharing it with other enamel manufacturers to help them avoid unnecessary problems.

When problems arise with enamel, the first step is to ascertain key production information: whether the pretreatment process meets standards (e.g., whether the substrate is thoroughly derusted and degreased), the drying method (different methods have different effects on the uniformity of the glaze drying layer), the coarseness of the glaze slurry (too coarse can easily lead to a rough glaze surface), the specific gravity of the glaze slurry (too thin will result in a thin glaze layer, while too thick will easily cause bubbles), the specific composition of the enamel frit, the grinding and adding ratio, and the final firing temperature and holding time. This information is essential for subsequent investigations and is crucial.

Test equipment

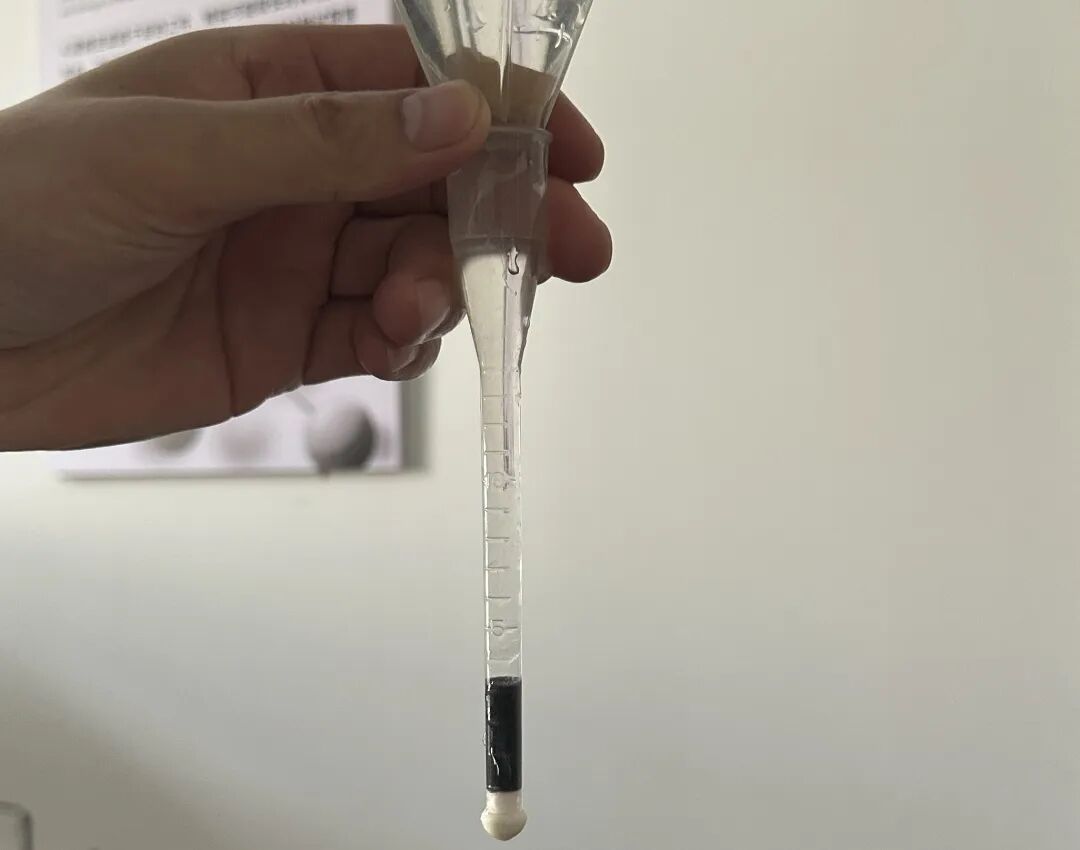

After understanding the basics, the first step is to assess the firing condition of the ground coat enamel frit—the ground coat frit is the cornerstone of enamel quality. Three methods are used to assess this: first, test adhesion (using the cross-hatch method to ensure the glaze layer remains intact); second, visually inspect the porcelain surface for pinholes, cracks, or delamination; and third, use a thickness gauge to check the porcelain surface thickness to ensure it meets process requirements. When providing technical services to enamel factories, Nolifrit technicians must carry a Bayer sieve, a thickness gauge, and a pycnometer. The Bayer sieve quickly determines the coarseness of the glaze slurry, the pycnometer accurately measures the specific gravity of the glaze slurry, and the thickness gauge confirms the thickness of the glaze layer. This combination of tools makes inspection more efficient.

Furthermore, familiarity with the glaze's properties is crucial. If a new brand or type of enamel frit is being used in production, it is recommended to test it with a small batch of samples to test its fluidity, expansion coefficient, firing range, and other properties. Only after confirming compatibility with the production process can mass production be implemented to avoid large-scale problems caused by glaze incompatibility.

Finally, I would like to share a tip on using ground coat enamel frit: In most cases, using a combination of high temperature + medium temperature + low temperature ground coat enamel frit can effectively expand the overall firing temperature range, reduce defects caused by slight fluctuations in furnace temperature, and at the same time improve the bonding strength of the glaze layer, further improving the product qualification rate.