Enamel Assembled Tank Ready-To-Use Powder: The Quality Choice for Enamel Can Manufacturers

In the production process of enamel assembled tanks, enamel frit plays a crucial role. As manufacturers of enamel assembled tanks, strict control over the selection of raw materials is essential, leading to a constant search for an enamel frit that can enhance product quality, reduce costs, and meet diverse demands.

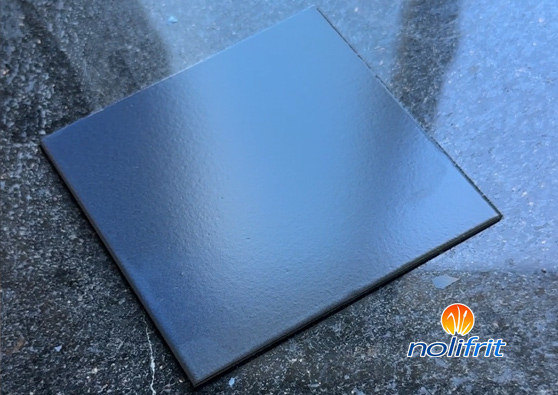

Nolifrit's enamel assembled tank RTU powder is specifically designed for enamel assembled plates (hot-rolled plates). Its excellent adhesion and corrosion resistance ensure that the assembled tanks produced have a high level of quality stability. These tanks are not only acid-resistant and corrosion-resistant but also maintain outstanding performance in high-temperature environments, significantly extending the product's lifespan. This is undoubtedly a major selling point for enamel assembled tank manufacturers and a key factor in gaining market reputation.

In addition to its outstanding performance, Nolifrit also offers a wide range of color options for the production of enamel assembled tanks. By adding various enamel pigments, such as chrome green and cobalt blue, manufacturers can easily customize assembled tanks in a variety of colors to meet diverse personalization needs. This flexibility not only enhances the market competitiveness of the products but also brings more business opportunities to enamel tank manufacturers.

Furthermore, Nolifrit's enamel assembled tank RTU powder is reasonably priced, offering high cost-effectiveness. By using this RTU enamel powder, enamel assembled tank manufacturers can effectively reduce production costs while ensuring product quality, thus increasing profit margins—an undoubtedly win-win choice.

Many enamel manufacturers have given high praise after using Nolifrit's enamel assembled tank RTU powder. One manager remarked, “Nolifrit’s RTU powder not only improved the overall quality of our products but also significantly increased production efficiency. Additionally, the professional services and technical support provided by Nolifrit made the process incredibly convenient and reassuring.”

Related Searches: