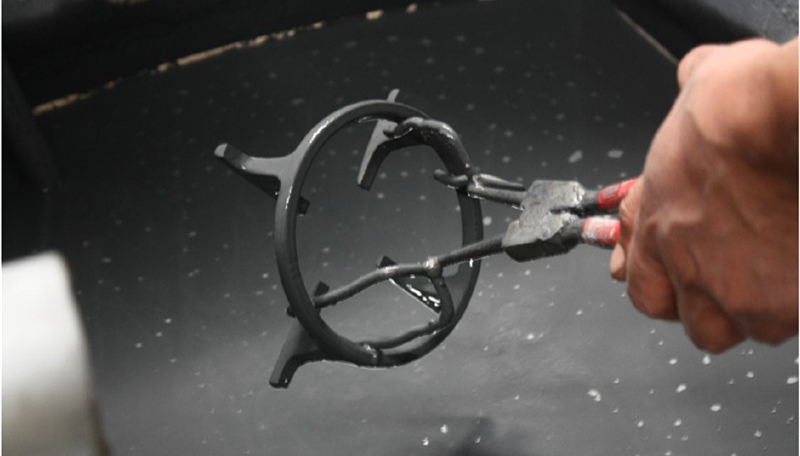

Dipping enamel coating in wet process

Wet process enameling is to coat enamel slurry to metal body. There are mainly 3 ways for wet process enameling: dipping, spraying and flow coating. First, let’s know about dipping enamel coating.

Dipping is the most primitive and easy way in enamel coating. It’s fit for product in single color. If metal body is small and with simple shape, we just need to dip it in enamel slurry and take it out after it adsorb enough enamel slurry, then wipe off redundant enamel slurry. If metal body is complicated, we will need turn it in enamel slurry and swing, turn or hook it to wipe off redundant enamel slurry. To achieve a uniform enamel coating .

The specific gravity and stop flow of enamel slurry is of crucial importance. Need to be measured constantly. When the stop flow of enamel slurry is low, it will need stop flow additive to adjust. For metal body with different sizes and complexities, there’re also different requirements for its specific gravity and stop flow.

1, For small product with complex shape. Specific gravity and stop flow of enamel slurry should be higher. The quality of enamel coating depends more on the worker’s operant level

2, For big product with simple shape. specific gravity and stop flow of enamel slurry can be lower. For the production of this product, dipping and swing can be done by one worker and other assistant works done by another operator. By this, enamel coating process is dispersed by specific workers, which makes enamel coating with high quality and more stable and the physical exhaustions of workers is also divided.

3, For product with multiple coating and firing, ground coat thickness need to be as thin as possible, to reduce the problems that happen in subsequent process. Especially for the product with decal, as the problem will mostly appear in decal firing. Traditional tools and facilities for enamel dipping is very simple, mainly include jar, pliers, grill. For products need special handle on the edge, there’re also special tools, such as: side wipe rubber, rolling case and plate. Those tools are all customized without any standard model for it.

In reasonable enamel coating process, enamel slurry should be coated on metal body with uniform thickness. It will make big difference to final product’s property. Also will affect the quality and appearance of enamelware.