Difference Between Enamel Pre-ground Powder and

Enamel Electrostatic Powder

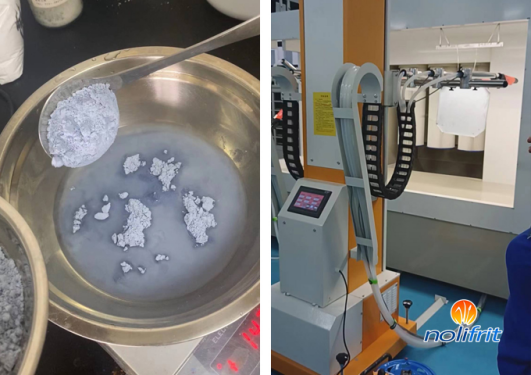

In the enamel manufacturing process, enamel frit is an integral part. In recent years, enamel pre-ground powder and enamel electrostatic powder, as new porcelain enamel (enamel powder) products, have brought production convenience to enamel manufacturers.

First, let’s take a look at the difference in enamel technology between enamel pre-ground powder and enamel electrostatic powder. Enamel pre-ground powder can generally be used directly after adding water and stirring, eliminating the cumbersome steps of ball milling for traditional enamel frits and reducing dependence on enamel technology. Enamel electrostatic powder requires specialized electrostatic spraying equipment, but the utilization rate of enamel can be as high as 97~98%, which is very beneficial to enamel production in the long run. More importantly, these two new glaze products not only save time and energy, but also reduce environmental pollution.

Secondly, there are certain differences in the application uses of enamel pre-ground powder and enamel electrostatic powder. With the development and upgrading of enamel frit products, enamel pre-ground powder is suitable for more and more enamel products, such as enamel water heater liner, kitchen stove, enamel oven, black primary gloss enamel for building decorative panels, etc. Hunan Noli's newly developed cast iron matte enamel pre-ground powder and black glossy one-time enamel pre-ground powder are favored by many enamel manufacturers.

Enamel electrostatic powder is suitable for larger enamel workpieces. In China, it is widely used in the high-end oven industry, especially built-in electric ovens. The inner pot and main exterior parts are all sprayed with electrostatic powder. Due to the characteristics of electrostatic adsorption, enamel electrostatic powder can better cover curved surfaces and uneven parts, making the coating more uniform and perfect.