Common Cast Iron Enamel Defects

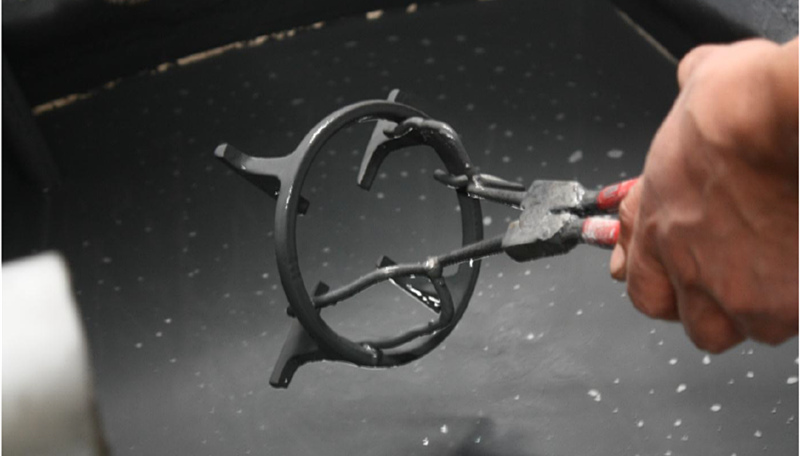

Cast iron enamel is generally used for cast iron oven grills, cast iron bathtubs and other products. Compared with steel enamel products, cast iron has higher carbon content and is more easy to cause enamel defects. In this article, Nolifrit enamel raw material manufacturer will introduce the defects of cast iron enamel in detail.

1. Causes of direct-on black matte enamel with bubble and holes: small holes on cast iron castings are poorly filled, large holes on castings are poorly spot welded, porcelain enamel layer is too thick, and over burned.

2. The causes of the cracking of the semi-melted white ground coat: the porcelain enamel layer is too thick and the drying is insufficient.

3. Causes of bubbles and holes on glossy enamel: too much impurities in the casting (especially the position of the riser), small sand holes on the casting are not well filled, the casting has cold partitions, many internal pores inside, the defect of ground coat layer is not repaired, ground coat layer is too thin or over-fired, ground coat layer is contaminated, the surface cover coat enamel slurry has impurities, the casting is partially chill, the annealing is insufficient, and the shot blasting is not enough.

4. Causes of porcelain enamel chipping off: the ground coat is contaminated, the ground coat or the first cover coat is not completely dried, the ground coat is damaged, especially the edges, the chill area is large, the casting has pores, cold partitions or impurities mixed, the wall thickness are too different, and the stress is too large during cooling.

5. Causes for the formation of different colors: the other unwished color dry powder are not wiped up, the gloves are stained with different color powder, there are different color powder on the blanket of the console liner, the burning frame or the transmission line. The dry color powder is fall off from the workpiece with insufficient drying.

6. Causes for the formation of watermark: water or sweat drops on the dry powder layer of the cover coat, and the powder is partially repaired with wet powder after drying.

Through the above introduction of Nolifrit enamel raw material manufacturer, I believe that everyone has a basic understanding of cast iron enamel defects. The production process of enamel products has two sources, one is chemical enamel melting, and the other is manufacturing of metal substrate. In the combination of two into one, then enter into process of firing for the enamel coating. The production process of enamel products is complicated, and errors in any link will cause defects in the final product.