Application of Sodium Nitrite in Porcelain Enamel

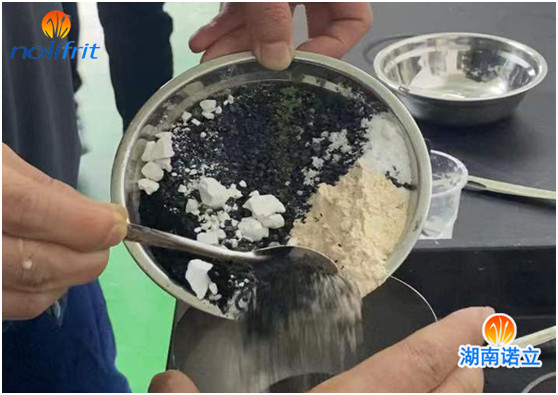

Sodium nitrite is one of the commonly used abrasive additives in enamel slurry. If sodium nitrite is used incorrectly, it may cause defects in enamel products. We once had customers who mistakenly added sodium sulfite as sodium nitrite, which caused the porcelain surface of the product to burn and the case of shrinking enamel.

Sodium nitrite can thicken the enamel slurry, has good retention performance, and at the same time will not cause the rapid precipitation of particles in the shaft slurry. The retention agent is essentially an electrolyte, and the so-called electrolyte refers to a compound that can be ionized into ions in an aqueous solution. Under the action of electricity, the colloid system can be solubilized to form a sol, or a sheet-like precipitation to form a gel. Most of the electrolytes can promote the coagulation of the colloid and play the role of a flocculant, and a few electrolytes can promote the decoagulation of the colloid and become thinner, and play the role of a decoagulant.

So what role does sodium nitrite play in enamel frit?

If sodium nitrite is added to the ground coat, it can inhibit rust, resist "copper head", and prevent reddish-brown spots caused by iron oxidation of the ground coat. If it is added to the cover coat, it can resist cracking, and it can effectively prevent cracking with acid-resistant enamel frit or stainless steel enamel frit.

When we use sodium nitrite, we should pay attention to controlling the content, as long as the minimum content can keep the enamel particles suspended and avoid precipitation. If it is added in excess, it will affect the processability of enamel, resulting in quality defects of enamel products.