Adhesion Judgment And Influencing Factors

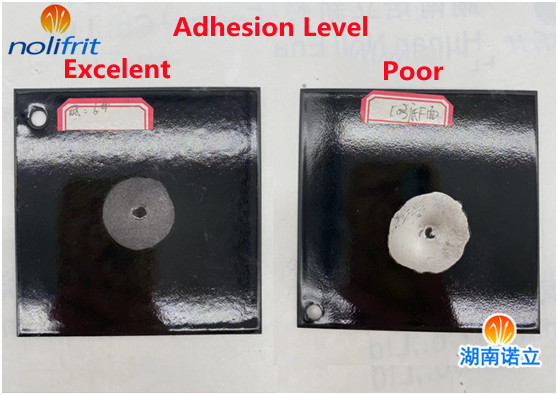

The adhesion performance of enamel frit is its most important mechanical performance, which directly determines the tightness of the ground coat layer and the metal blank. In the world, the adhesion strength of enamel is usually tested by the 5-level method. It is judged by the exposed metal performance of the ground coat layer of the enamel test sample after being impacted. There are filaments, nets, blocks and light plates. The shape performance is the best, and the light board performance is the worst.

The adhesion strength of enamel has a great relationship with the composition and amount of the adhesion agent introduced into the enamel frit. The adhesion agent can deepen the erosion of the enamel frit on the metal surface. The greater the erosion effect, the better the adhesion. Among them, the adhesion agents NiO and CoO only need to introduce a small amount (NiO: 1%~1.5%, CoO: 0.5%) to achieve a good adhesion effect, and the effect is better if they are cited at the same time. Or grinding and adding some Sb2O3 and MoO3 in the enamel ground coat can also improve its adhesion strength.

The adhesion performance is also closely related to the surface tension of the enamel frit. The enamel with high surface tension and poor wettability cannot produce good adhesion with the metal body.

The adhesion performance is also related to the surface condition and cleanliness of the metal blank, so it is necessary to do a good job of pretreatment of the metal surface, and the metal blank with a rough surface has better adhesion strength.

If you want to improve the adhesion strength of enamel, you must also pay attention to the degree of melting of the ground coat. Whether it is over-melting or incomplete melting, it will lead to poor adhesion and may also cause defects in other enamel products. There is also the firing process of the enamel product itself, neither over-firing nor underfiring.